Introduction to | Materials Informatics

Materials Informatics is used across products, materials and chemicals, anywhere where the properties of a substance give competitive advantage.

|

What it does

Cuts through complexity

|

What it enables

Efficiency in developing and producing products, materials and chemicals |

How it works

Guiding experts’ analyses and learning from their choices

|

What Materials Informatics does:

- Today’s challenges are a complex balance of competing demands, and the experimental data used to find solutions are complicated, subtle and expensive.

- Informatics uses computational techniques and statistics to analyze and interpret this data far more efficiently than a human could.

- AI models help us understand trends and relationships in our data, and suggest recipes to achieve our goals.

To create innovative, high-performance materials, traditionally scientists have needed to test many ideas physically. Materials Informatics gets AI to run many, many virtual experiments, so they can refine their theories and focus on the most promising options.

Why Materials Informatics matters:

- New products can take years to develop, using specialized knowledge, trial-and-error, and luck. Materials informatics accelerates this.

- By accelerating innovation, product experts can be more agile in responding to customer requirements, production issues, supply shocks and regulation.

- As a society, we can expedite the science we need to solve our biggest challenges.

Read our Case Studies to see how we are already delivering benefits to our customers and the environment.

How Materials Informatics works:

- Computers are good at organizing complex data from a variety of sources into a form that a researcher can explore. This includes seeing the effect of a range of ingredients and manufacturing processes on the final characteristics of an end product.

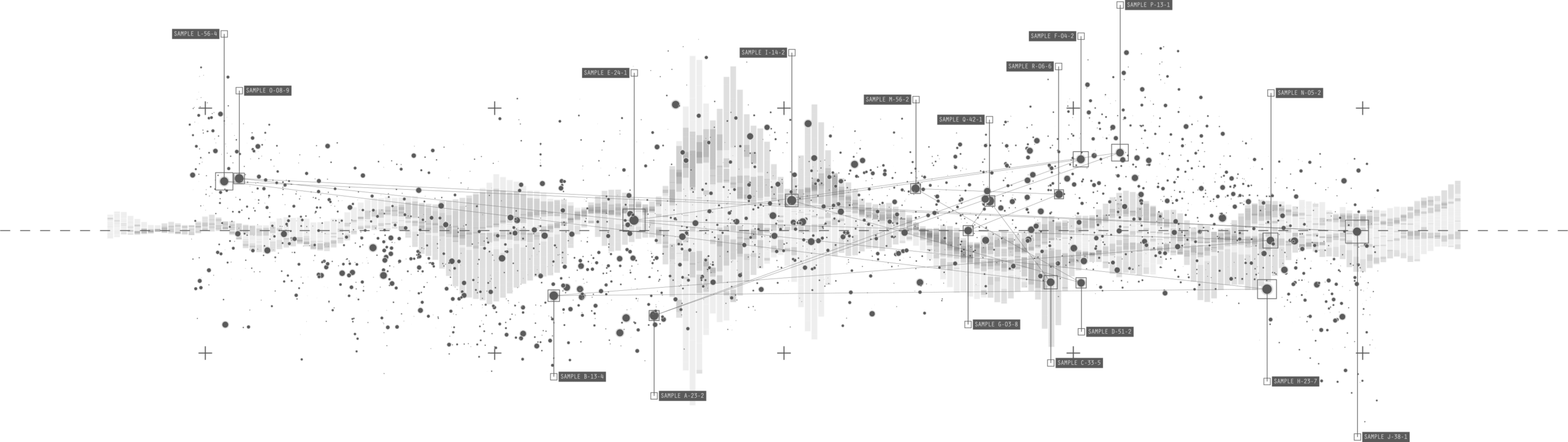

- AI models train themselves to find patterns in data and make predictions.

- Product experts refine models, using physical insight and restrict suggested recipes to those that use feasible ingredients and practical processing parameters.

- Target final properties are set and recipes suggested. Statistical techniques are used to understand which experiments are more exploratory and which are a safe bet.

- An iterative process of strategic experimentation and retraining the AI model with the new data then guides researchers to their targets with up to 80% fewer experiments than traditional methods.

Example

A chemist might want to create a clear material without using a key ingredient. The model might propose a ranked list of 100 ways to create this. The chemist chooses the most promising options to test in a lab, and then the model retrains with the new results, becoming smarter and suggesting new, better recipes.

FAQs

-

What is materials informatics?

Materials informatics is a discipline that uses computational techniques like AI and machine learning with datasets related to materials and chemicals properties, structures, and processing conditions, in order to develop new materials and improve existing ones.

-

How does materials informatics benefit materials science?

By leveraging data-driven approaches, materials informatics can significantly reduce the time and cost associated with materials and chemicals discovery and development. It allows researchers to predict material properties, optimize processes, and identify new materials with desired characteristics.

-

What are some challenges in materials informatics?

Challenges include:

- Data quality and availability. Materials and chemical experiments cost money and take time, so data sets are usually small. There is also a lot of nuance and complexity in making materials and chemicals that, if not recorded alongside the property results, renders the data useless for experimental design.

- Integrating heterogeneous data sources. Materials and chemical data can have many forms, from simple numbers and categories to complex molecular representations and images. Data can come from a variety of sources and researchers may have recorded data in different ways, using different units, etc.

- Developing interpretable models. Scientists always want to know why – so explaining the reasoning used by the AI model is very important. Moreover, understanding why a model is responding the way it is can give valuable insight into the physical nature of the underlying process, generating value far beyond the predictive capability alone.

- Scaling computational approaches to handle 20-100 dimensions and complex targets and constraints. In industry there are time constraints, so methods are needed that handle complex queries in short time frames. Real problems are often about tradeoffs; optimizing a product typically requires considering many dimensions at once. Citrine Informatics has spent more than a decade and $100 Million investment into solving these challenges.

Over more than a decade, Citrine Informatics has invested more than $100 Million to overcome these challenges and make AI for materials and chemicals successful and practical for our customers. This blog covers how we have overcome these challenges.

-

How does materials informatics impact industry?

In industries where materials and chemicals are important, such as specialty chemicals, plastics, coatings and personal care, materials informatics can lead to faster development cycles, improved materials performance, agile response to shifts in supply chains, and cost savings. It can also facilitate innovation by enabling the exploration of new materials combinations and properties. Read our Case Studies to see real examples of this.

-

What machine learning techniques are commonly used in materials informatics?

Common techniques include supervised learning (e.g., regression, classification), unsupervised learning (e.g., clustering, dimensionality reduction), and reinforcement learning. Deep learning methods, such as neural networks, are also increasingly used for complex data types like images and simulations, though in most cases the availability of data limits use of deep learning techniques. Citrine Informatics’s sequential learning approach represents a unique optimization framework that is data-efficient and can handle bigger, real-word problems (dozens of variables, multiple objectives, noisy data, and real-world constraints) with ease.

-

What skills are needed to master materials informatics?

The latest Materials Informatics software – like the Citrine Platform – are no-code systems using an understandable graphical user interface to perform an AI workflow. To get the most out of such a system you need a deep understanding of the materials and chemicals you are working on, and a basic understanding of concepts like uncertainty and optimization.

-

What are some examples of successful applications of materials informatics?

Successful applications include the reformulation of chemical products without problem chemicals like PFAS, optimization of chemical processes to increase yield and reduce energy use, development of aerospace-grade materials for additive manufacturing, and identification of novel organic semi conductors. You can read all about our success in these Case Studies.

-

How does materials informatics handle the complexity of materials data?

Feature engineering is used to distill complex data into manageable and insightful forms. Feature engineering is the process of deciding which bits of information could be useful to a model in predicting the properties of interest and getting them into a format that maximizes a model’s ability to learn. Domain knowledge is crucial for this process. While many features in materials and chemicals can be generated quite easily by converting molecular structures and chemical formulas into more detailed representations, there are often nuances that are best leveraged by letting domain experts (those that know their process better than anyone) break down what’s actually important. It is also key to have systems that can record all the conditions at play during sample preparation and record process steps and their parameters as well as ingredients and their amounts.

-

What benefits does AI bring to chemical discovery and development?

AI accelerates the discovery of new formulations and materials by guiding experimentation in the most efficient path.

AI leads to better performing materials and formulations, because more target properties and constraints can be worked on simultaneously.

AI can be used to:

- optimize costs and sustainability as well as technical performance.

- increase sales by improving customer responsiveness.

- be more agile by quickly changing formulations when supply issues, customer requirements or regulations change.

Read our Case Studies for examples.

-

Can AI improve chemical manufacturing processes?

Yes. AI can optimize chemical manufacturing processes during the scale-up processes by determining optimum processing parameters, and during production by analyzing sensor data to predict equipment failures. It also enables real-time monitoring and control, enhancing production efficiency and safety. The Citrine Platform focuses on simultaneously optimizing processing parameters and formulations. It has been used to reduce production costs by both increasing yields and reducing energy use.

-

How does AI help in sustainability efforts in the chemical industry?

AI supports sustainability by enabling a transition to renewable feedstocks; increasing yields in chemical recycling; enabling consistency in mechanical recycling; reducing energy use and carbon footprints; and reformulating to remove hazardous chemicals like PFAS. This Webinar on increasing the sustainability of plastics will tell you more.

-

What challenges does the chemical industry face when implementing AI?

The challenges are two-fold. Firstly, there is an education piece. There are many myths about AI for chemicals that are holding the industry back. For example, there is a perception that you need large datasets and specialist data science or coding skills. The second challenge is common to any technology, a mix of fear of the unknown and an inertia from the extra effort that you need to start something new can result in slow adoption unless the change is led well. This White Paper, pulls together a decade of experience in rolling out AI and gives advice on how not to fail.

-

What does a chemist need to learn to use AI in product development?

When using the latest AI for chemistry platforms, users do not need special skills in data science or coding, but they still need to get used to a new way of working.

- They need to understand their role in “featurizing” the data i.e. distilling which inputs an AI model needs to predict properties.

- They need to make sure that in future experimental data is recorded consistently and in detail.

- They need to understand how to create a search space by applying constraints to the raw materials allowed and the processing parameters that can be set.

- They need to learn how to learn from the AI model.

- They need to understand how to analyze and select from candidate experiments and best choose what to take to the lab.

- And finally and most importantly, they need to understand that it is the accuracy of uncertainty estimations that drives time savings in AI for Chemistry, rather than the standard measures of prediction accuracy like R2.

-

What role does AI play in supply chain management for chemicals?

As well as enhancing supply chain efficiency by forecasting demand, AI can be used to identify critical raw materials that need extra buffer stock and quickly reformulate when there is a raw material shortage. The Citrine Platform is used to identify substitute ingredients or raw materials when regulation makes this a necessity or in order to have multiple vendors for resiliency. This Webinar goes over this topic in more detail.

-

How does Citrine keep customer data secure?

Citrine Informatics is ISO 270001 accredited. You can read about data security in detail here. In summary, each customer has their own encrypted instance of the platform, and only they can access their data and their models. Data and models are not shared across customers and even Citrine employees need permission from customers to access their data when helping them on projects.

-

Who gets the Intellectual Property when AI for materials and chemicals is used?

Different companies have different business models. Citrine Informatics focuses on selling software and does not acquire any rights over the Chemical and materials IP generated by customers using the platform. More detail in this Blog.

-

How does AI work?

There are different types of AI, but at a high level, the machine learning models that Citrine Informatics use essentially look for connections between inputs (raw materials, processing parameters) and outputs (final material properties) and then creates an algorithm to predict the outputs based on the inputs. However, predictions are not as effective if you don’t know how good your prediction is. Therefore, the uncertainty of the predictions is also estimated and this is the extra information that our customers leverage to decide which experiments to take to the lab next.

-

How do you get scientists to adopt AI?

Firstly, it is important to give them ownership of the technology, by enabling them to (a) use the software directly through a graphical user interface – no code, (b) learn from the AI model – no black box, and (c) ensuring that they still chose which experiments to carry out.

Secondly, it is good to have a successful first project carried out by an enthusiastic team. Choose the team carefully (involving a respected technical leader, open to new technology) and make sure the project generates business value (clear obstacles to success, such as too little lab time available, and ensure business value can be measured).

Lastly, shout about the success and set expectations that AI is the new normal.

This White Paper goes into more detail on the change management aspects of rolling out AI.