Executive Summary

The Alliance for the Development of Additive Processing Technologies (ADAPT) and its partners used the Citrine Platform to create a new, additively manufactured door hinge for MRAP light tactical vehicles in a research and development project funded by TARDEC. This resulted in:

- FASTER DEVELOPMENT

Using data and AI, build parameters were dialed in faster than could have been done otherwise - 50% STRENGTH INCREASE

Stronger hinges than previously available leading to reduced failure - 100% INVENTORY REDUCTION

On-demand hinge production in the event of hinge failure - 84% COMPLEXITY REDUCTION

Reduction from a 6-part hinge to a 1-part hinge - 38% WEIGHT REDUCTION

Lighter hinge geometrically optimized with high performance materials

The Challenge

In 2007, the U.S. Department of Defense began a program to produce Mine-Resistant Ambush Protected (MRAP) light tactical vehicles. In response to changing threats in the field, the cab doors were later modified; adding a 400-lb. armor plate to the existing 800-lb. design to better protect soldiers inside the trucks.

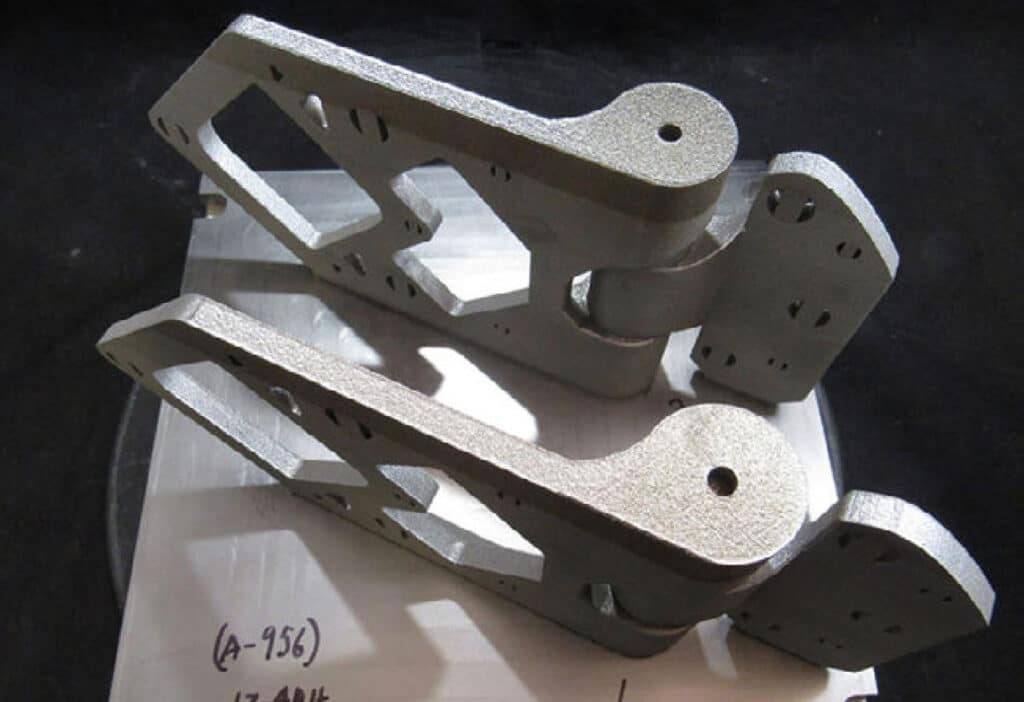

Unfortunately, the increased armor weight exceeded the design strength of the doors’ hinges (Figure 1), causing the hinge to fail. In some instances, doors fell off in the field while on patrol in Afghanistan and Crimea, leaving soldiers to determine how to reattach a 1,200-lb door to get themselves and their vehicle back to safety.

Hinge failure removed some vehicles from the battlefield for as long as two years because of the lead time for OEM-supplied hinges: production, delivery, and installation. At times, the Army was forced to transport the vehicles back to the US, adding tremendous cost and leaving warfighters unprotected.

The performance problems and supply chain challenges led the US Army Tank and Automotive Research, Development, and Engineering Center (TARDEC) to seek an alternative design for replacement hinges. Due to the significantly shorter lead time offered by additive manufacturing (AM), TARDEC brought the challenge to the Alliance for the Development of Additive Processing Technologies (ADAPTSM) Center.

The Solution

The ADAPT Center and its partners at Citrine Informatics, Elementum 3D, and the University of Pittsburgh used data-driven additive manufacturing (AM) to reproduce and redesign the hinges.

The initial phase of this program consisted of replicating and characterizing the fatigue performances of direct replacement parts with AM. Using the Citrination platform and preexisting data from other ADAPT projects, the team achieved an 84% prediction accuracy of build parameters on the first print, produced using a completely new materials/printer combination. Although this first build simply allowed the team to replicate the design of the OEM hinge assembly, a datadriven approach reduced the time to replicate existing performance characteristics and allowed the group to focus on how to create a lighter, stronger hinge.

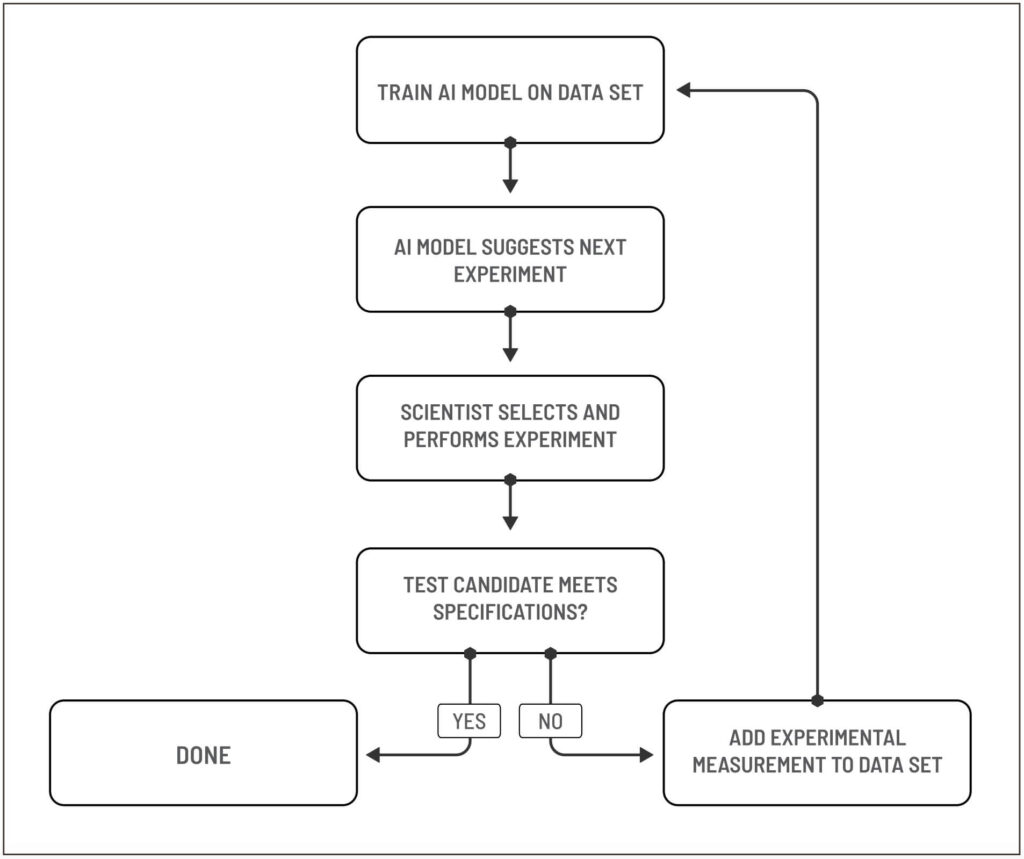

Using a design and build strategy that incorporated new modeling, simulation and experimental test data into the Citrination platform, the team quickly produced quality specifications for temporary or permanent replacement parts. This iterative method – build, test, then use artificial intelligence (AI) to evaluate and update print parameters–significantly reduces development and qualification time (Figure 2). Further testing verified that AI-proposed settings like build direction and build speed produced a final product that met or exceeded the required performance in terms of strength, weight and durability.

Using this data-driven approach and the design for additive principles, the team:

- Reduced the number of parts in the hinge assembly from six to one

- Reduced the maximum stress in the hinge joints from 900 MPa to below 90 MPa (an order of magnitude increase in the factor of safety).

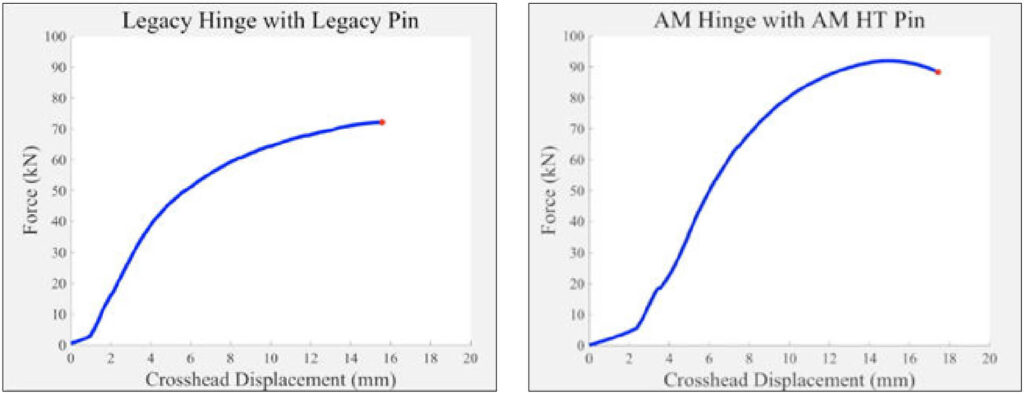

- Increased the yield strength of the printed hinge compared to the traditional replacement (Figure 3)

Then, in the final stage of the process, ADAPT partnered with Professor Albert To at the University of Pittsburgh to optimize the geometry of the designed-for-AM hinges, which reduced their weight by 38% relative to the original hinge assemblies (Figure 4).

Impact

The data-driven, ML guided methodology that the ADAPT researchers applied to the redesign of the MRAP hinge reduced development time and resources normally consumed during the standard trial-and-error process parameter tuning approach.

Key design and performance improvements from the original OEM hinge include:

- Single-piece design vs. six pieces for the OEM part

- Significant increase in strength to avoid the breakage the OEM hinges were suffering

- Part design that can be printed on demand, requiring no inventory

- Faster part fabrication and delivery – the redesigned hinge can be printed in 24 hours and finished and delivered in days – not weeks, months or years

A set of MRAP hinges built using ADAPT’s Optimize for AdditiveSM strategy are ready for ground vehicle testing by the Army in mid-2019.

References

- https://adapt.mines.edu/tardec-program/

- https://adapt.mines.edu/machine-learning-drives-am-research-and-enables-resilience/