Executive Summary

ACCELERATED RESEARCH EFFORTS

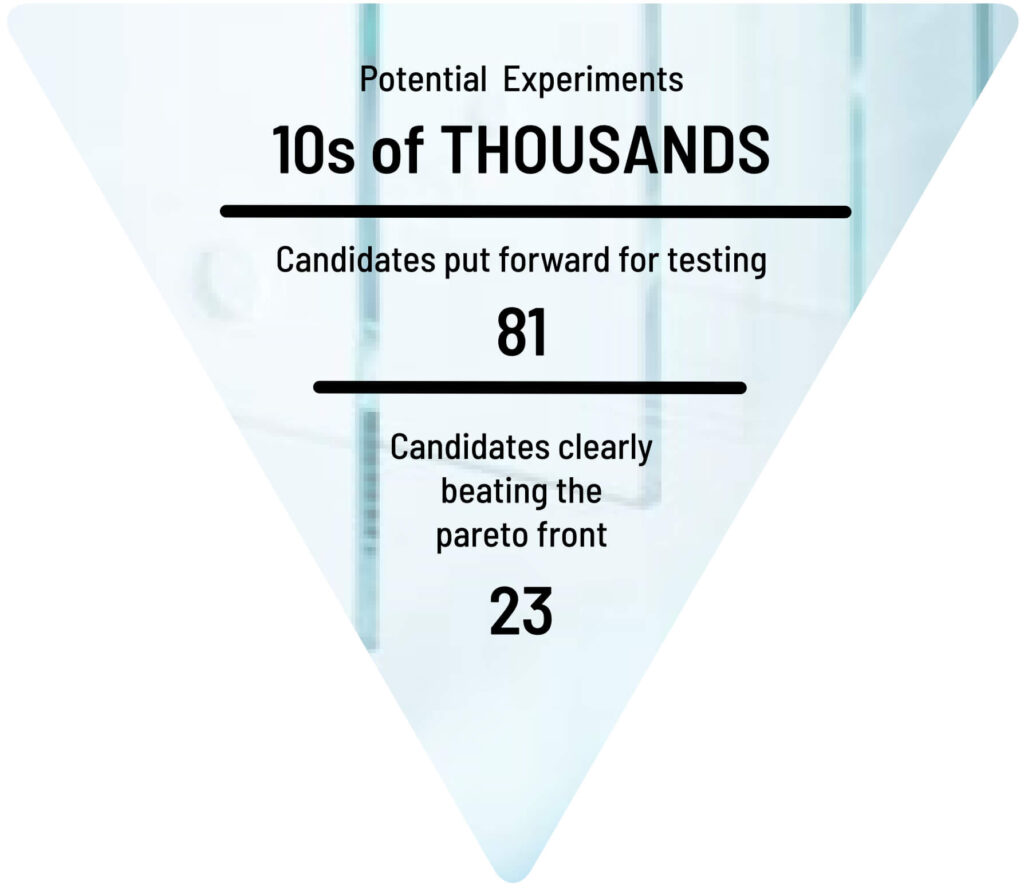

5 weeks to find a candidate above the Pareto front, ~8 weeks to evaluate all substrate options

NEW INSIGHT

Identified substrate with high potential for outperforming existing product line

PERFORMANCE IMPROVED

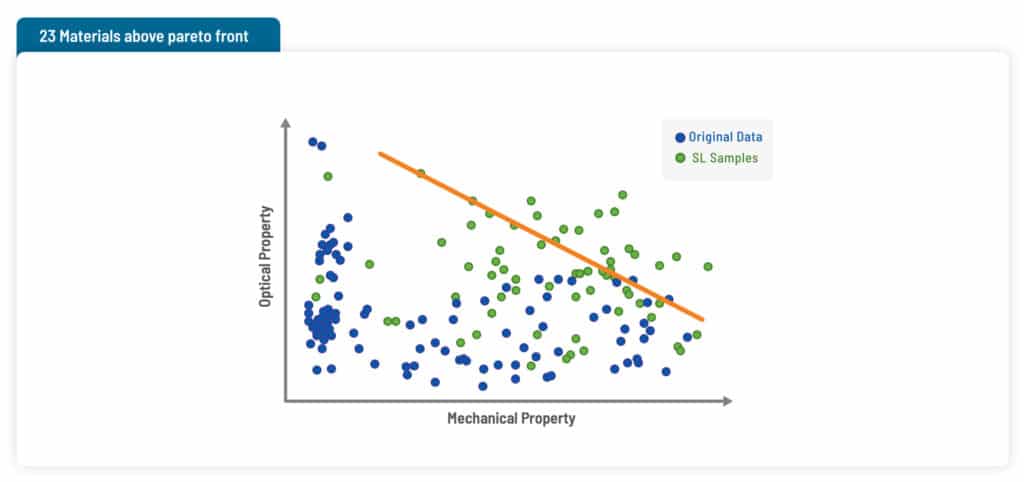

23 higher-performing candidates with better optical and mechanical properties

REUSABLE AI MODEL

Model reused to evaluate processing parameters with 50% reduction in set up time

The Challenge

For our customer, a glass manufacturer, optical and mechanical property profiles determine the target applications, but optimizing both at the same time is difficult. Newly developed materials must also be easily manufacturable, in large volumes, at low costs. For a target application, the glass manufacturer wanted to optimize one particular mechanical property and one optical one while imposing a processing constraint. To achieve these performance criteria, the customer could change the selection of the substrate material and/or the processing parameters.

AI-enabled Digital Strategy: This customer is undertaking a global initiative to digitalize the business to reduce costs and increase innovation. They are evaluating the ability of the Citrine Platform to enable their R&D team to be data-driven in their experimental design.

Glass optimization project: The customer identified tens of thousands of different possible candidate materials, but there were only two measured samples that fit their manufacturability criteria. It was therefore necessary to use data from candidates that didn’t meet all the criteria and extrapolate to find new candidates – via a process called transfer learning.

The Approach

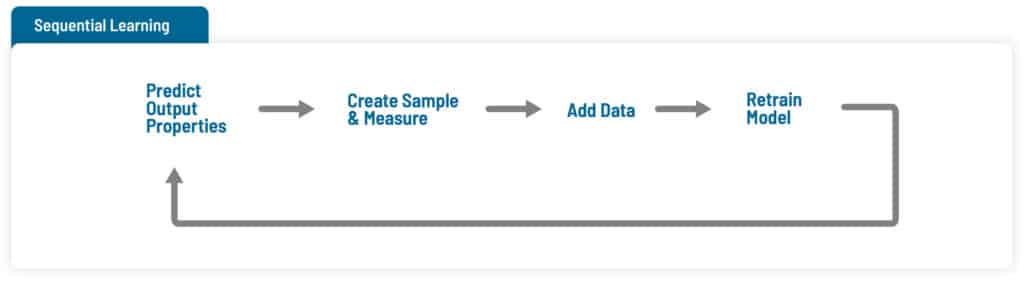

The customer’s research scientists iteratively trained and improved a Machine Learning model – a process called sequential learning. An initial model was trained on existing data from successful and “failed” experiments to predict the properties of new materials close to the two materials that met all the acceptance criteria. The team then synthesized a small set of new samples based on these predictions. The scientists tested the materials, uploaded the data, and then retrained the model. They then ran the model again to get new suggested materials to test. They did this until they met the desired performance criteria. In addition to predicting properties of the new materials, the Citrine Platform also generates uncertainty calculations for these predictions, which helped the scientists identify both opportunities to improve the model and promising new candidates.

The Results

In just 18 weeks, our customer found 23 materials that met the performance criteria and had better optical and mechanical properties than anything in the company’s portfolio. This required only 81 samples to be prepared and tested.

Strategic Direction

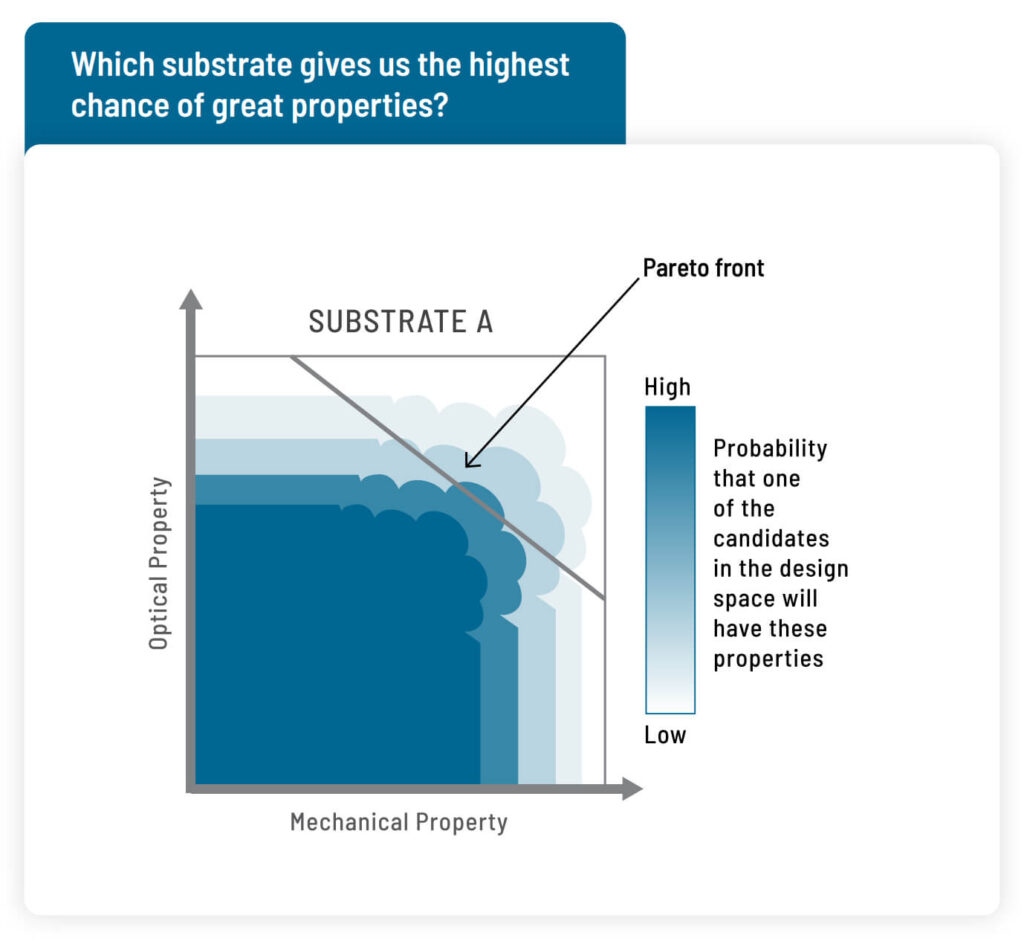

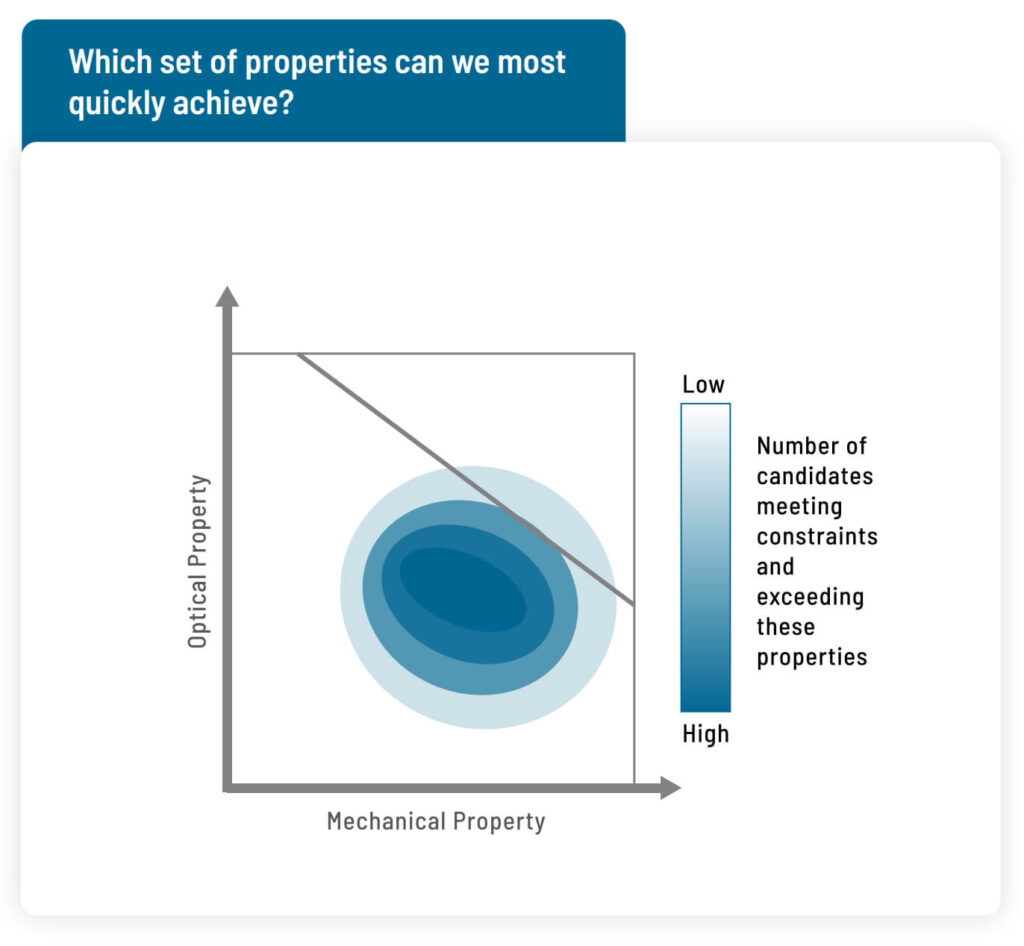

The customer had an important choice to make regarding R&D project direction. Selecting the right substrate was critical to meet performance targets. Using the Citrine Platform, the customer identified which substrate a) had a candidate with the highest probability of the best performance, and b) which substrate had lots of high performing candidates, so that finding those candidates was likely to be quicker. This information allowed the R&D team to make data-driven decisions on the investment of time and resources, reducing risk and increasing the likelihood of success.

Clear visuals focus the research portfolio on the best chance of success.