Revolutionizing Manufacturing with Scrap: A Vision for Point-of-Need Production in Austere Environments

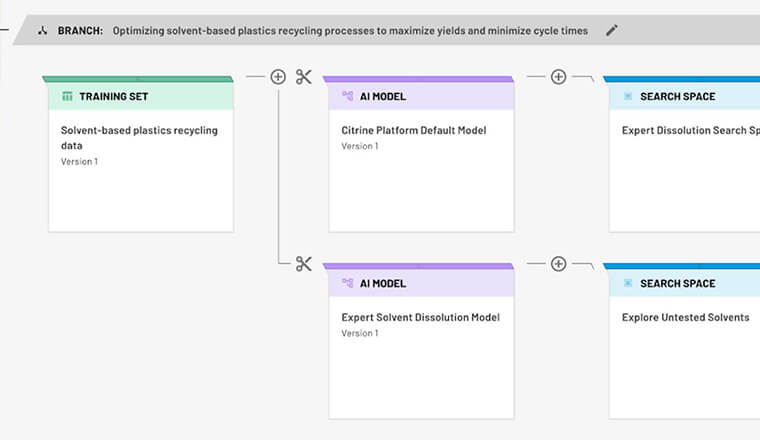

Global supply chains are facing increasing challenges, highlighting the need for new approaches to material production. One promising avenue involves developing methods to create high-performance materials from low-quality, variable...