Who We Help

The Citrine Platform is more than an R&D tool. It helps companies in a variety of industries create better materials and formulations, responding quickly to changing market and regulatory demands. It also enables business functions across these companies to exceed their own performance goals. We put the power of AI to work for teams of all kinds, allowing them to rethink what’s possible.

Who we help: Business Functions

From the lab to the corner office, the Citrine Platform helps your teams get more critical work done.

See how Citrine adds value to these teams:

-

Product Developers and Materials Engineers

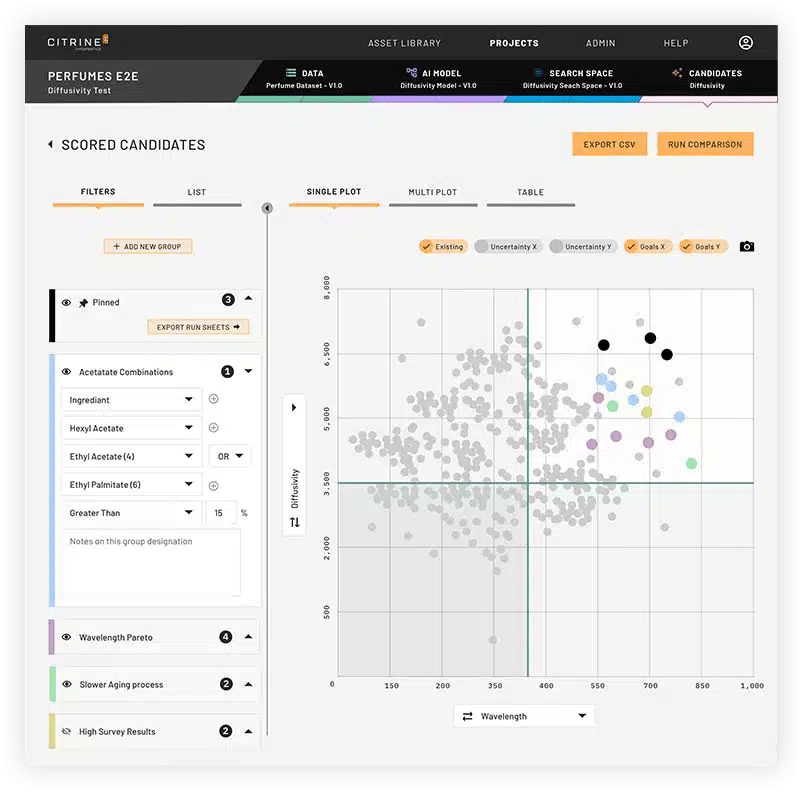

- Define target performance specifications

- Encode domain knowledge to improve AI-model performance

- Use Sequential Learning to replace traditional design of experiments to determine which candidate materials to test next

- Dramatically reduce the number of experimental iterations required to find high-performance materials

-

Data Scientists

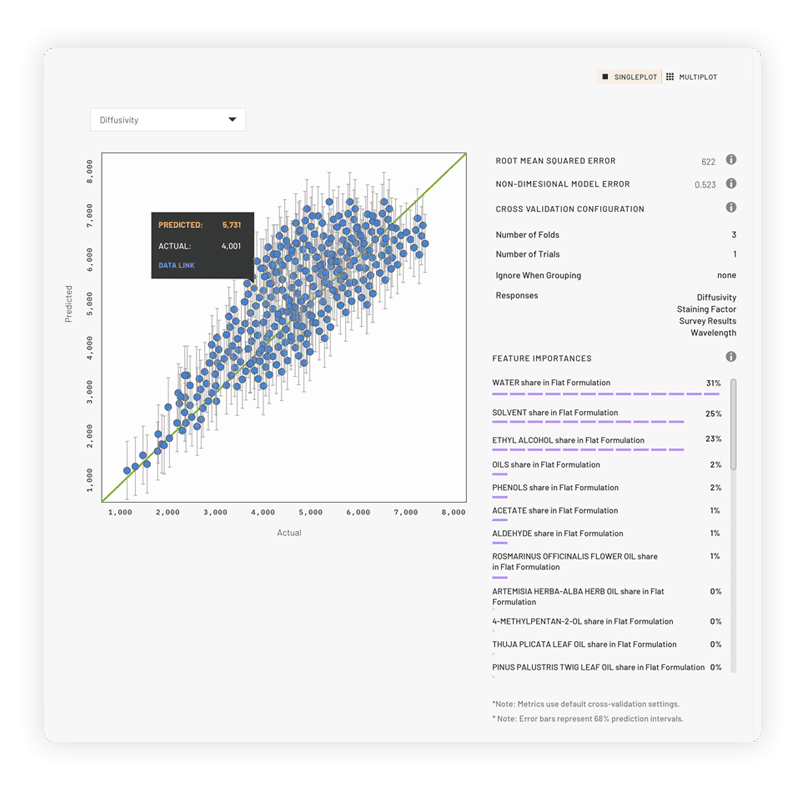

- Train, validate, and test AI models

- Design graphical AI models

- Perform feature selection and assess model uncertainty

-

Data Managers

- Upload, structure, and link data files from each step of the materials process history

- Examine, filter, and edit data

- View data in graphical materials process histories or structured tables

- Provide guidelines to promote consistency across an organization

-

C-Suite and Business Unit Executives

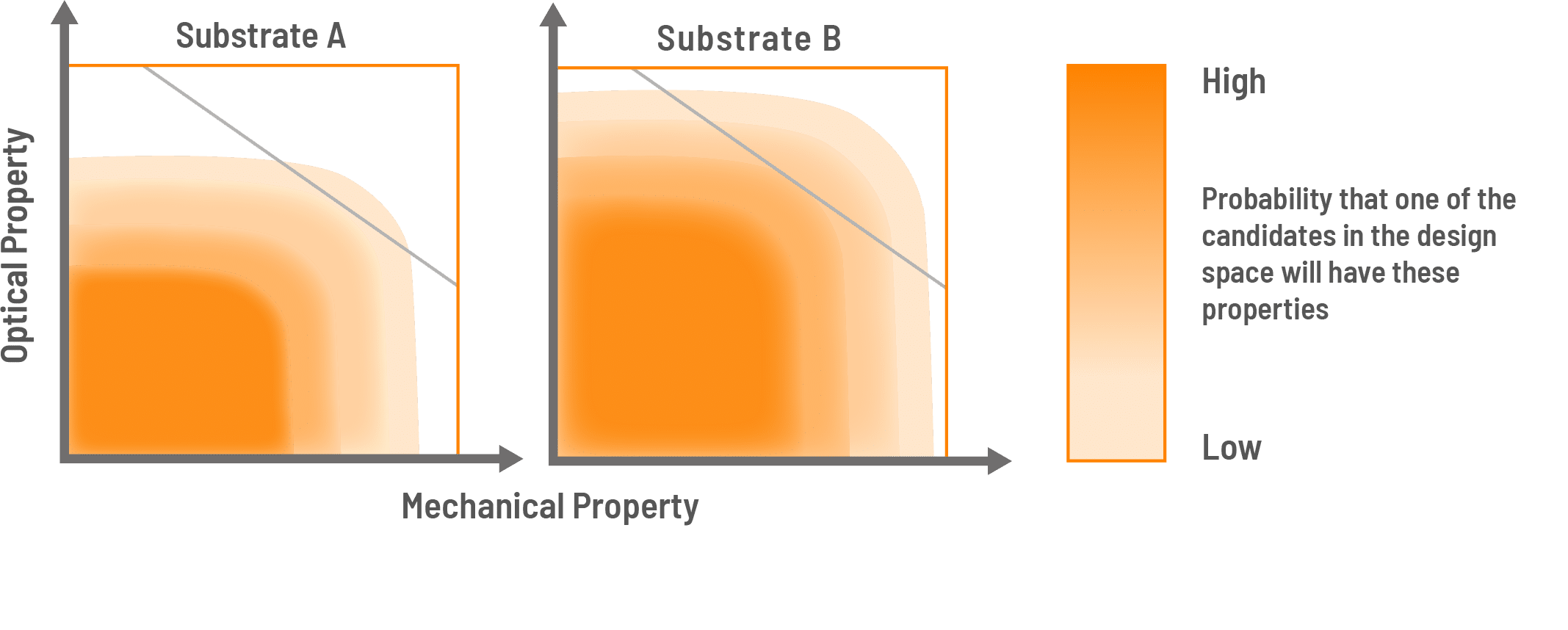

- Evaluate current product portfolio performance across multiple performance dimensions

- Quantitatively assess risk-reward trade-offs across the whole product development portfolio

-

Compliance Managers

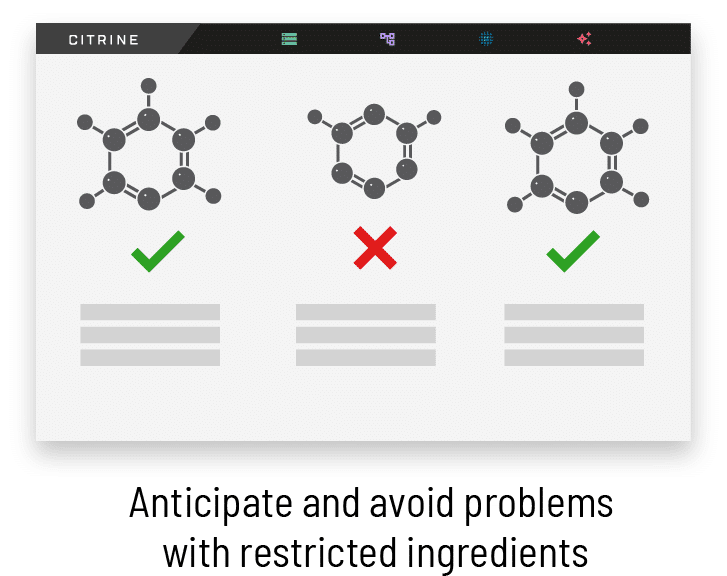

- Incorporate restrictions on sanctioned materials early in development process, avoiding investment in unusable candidates

- Evaluate suitability of emerging candidates regarding permissible sources and uses

- Use graphical interfaces to access technical information without specialized training

-

Sales and Marketing Executives

- Advise on perceived market demand for feature combinations

- Understand portfolio performance characteristics

- Use graphical interfaces to get access to technical information without specialized training

-

Supply Chain Managers

- Weigh in on implications of switching to different materials

- Improve negotiating position by consolidating and optimizing inputs within existing product portfolio

- Use graphical interfaces to get access to technical information without specialized training

-

Production and Manufacturing Executives

- Get early insight into potential changes to operational processes

- Use graphical interfaces to get access to technical information without specialized training

-

Finance Managers

- Provide input on cost/benefit tradeoffs for potential formula changes

- Use graphical interfaces to get access to technical information without specialized training

Who we help: Industries

Citrine’s AI platform can transform the way companies make virtually anything. Whether your goal is faster product development, supply chain resilience, becoming more responsive to customers, optimizing costs, regulatory adaptability or even improved sustainability, we can show you a new way to think about what you manufacture.

Featured Industries

Other industries we help

-

Building Materials

The Citrine platform helps construction material and concrete companies develop high-performing, sustainable products that meet complex regulatory requirements and overcome supply chain challenges.

Developing these low-cost, high-performing, sustainable products can be a challenge. The Citrine platform helps building materials companies accelerate R&D and increase confidence in R&D decisions. Our software platform combines smart data infrastructure and cutting-edge Machine Learning to accelerate innovation, so our clients can continue to build the future.

“I wouldn’t have come up with those candidates and decided to take them to the lab, if not for the AI predictions from Citrine.”

– R&D Scientist, Technical Ceramics ManufacturerBuildings materials companies can use the Citrine platform to:

- Optimize material properties when using locally-sourced raw materials

- Develop new more sustainable products and processes

- Improve customer responsiveness

Download the case study

Read how raw material catalogs can be rationalized and product cost optimized using the Citrine platform.

-

Batteries

Lithium-ion battery development is time-consuming and expensive due to the high chemical complexity of the system and long qualification times. Citrine accelerates our partners’ R&D timelines to achieve novel, differentiated battery technology, whether the technology is electrolyte formulation, additive discovery, anode and cathode creation, or process optimization.

Our AI’s ability to model a hierarchical system enables a totally new kind of battery modeling. If you start with individual components: cathode, anode, electrolyte, separator, or any other component, our AI can use your historical data to refine recipes to improve performance. But a battery is so much more than any one of these components. If you have AI models for each of your components, you can connect these models and enable system-wide optimization, leading to the highest possible performance for the entire battery.

Citrine’s tools serve as a powerful cross-team enabler. The intuitive graphical interfaces show the exact history of materials information for final cells, eliminating the heritability problem when the development of individual aspects of the battery (cell fabrication, cathode, anode, and electrolyte) are happening on different teams at different times. Native visualization tools let you spot gaps in data, outliers, and trends, which can be immediately useful in AI-guided experiment design.

“Citrine’s approach is essential to our company’s success.”

– Chairman of a high-performance automotive battery companyBattery manufacturers can use the Citrine Platform to:

- Make data-driven decisions about material selection.

- Use surrogate tests as predictors of lifetime cycle performance.

- Only move high-probability candidates forward for expensive, long tests.

- Uncover unintuitive combinations of materials uniquely suited to your battery chemistry.

Download the eBook

Better batteries with higher energy density and the ability to charge quickly are needed to enable the energy transition. This eBook explores how AI can be used to reach ambitious battery property targets quickly, through material development, battery configuration optimization and improved battery testing.

-

Ceramics and Glass

The Citrine Platform helps industry companies develop high-performing, more sustainable products in record time with a combination of materials-specific AI and smart data infrastructure.

Whether you’re making architectural products, the latest innovative technology for consumer applications, or products for extreme environments, the Citrine platform can increase your agility and efficiency.

“I wouldn’t have come up with those candidates and decided to take them to the lab, if not for the AI predictions from Citrine.”

– R&D Scientist, Technical Ceramics ManufacturerCeramics and glass companies use the Citrine Platform to:

- Efficiently optimize materials and processes

- Enable multi-property design of materials: “lighter and stronger,” not just “lighter or stronger”

- Explore “what if” scenarios before committing to expensive capital expenditures

- Figure out how to avoid using “problem” materials

Download the case study

Learn how a leading glass manufacturer developed a differentiated product using new processing equipment in just 8 weeks using the Citrine Platform.

-

Metals and Alloys

Citrine’s metals and alloys customers are accelerating the development of lighter, stronger, less energy intensive products to compete with a growing number of materials in key customer markets.

Meanwhile, our customers are also moving toward more sustainable processing technologies and improving carbon capture: good for business, and good for the world.

“ [The Citrine Platform] has started to change how we think about developing products and processes.”

– Materials Scientist, Industrial Consumables CompanyMetals and alloys companies can use the Citrine platform to:

- Optimize alloys and heat treatments, and rapidly tailor these to specific OEM requirements

- Work around price volatility in alloying elements

- Discover better catalysts

- Accelerate light weighting design efforts

- Develop alloys suitable for Additive Manufacturing

Download the case study

Learn how HRL worked with Citrine to be first to market with an Al alloy suitable for 3D printing. Research time was reduced from years to days.

-

Consumer Electronics

The Citrine platform helps consumer electronics companies develop high-performing materials and components for cutting-edge products.

Materials science researchers must juggle competing demands to make components lighter, stronger, less expensive, more resistant to water and corrosion, and more. The Citrine platform helps our customers push materials properties to their limits and design around critical materials and supply chain disruptions.

“This work demonstrates the utility of using the sequential learning methodology to design experiments for the discovery of novel materials.”

– Nobuyuki Matsuzawa, Director, PanasonicCPG companies can use the Citrine platform to:

- Efficiently explore large search spaces making it more likely to discover truly innovative materials

- Help teams understand how changing ingredients and processes will affect if removing critical elements will harm performance

- Co-optimize materials and devices to remain at the cutting edge

Download the case study

Learn how Panasonic was able to reduce processing costs by discovering and patenting 4 new soluble organic semiconductors with 25% higher performance (hole mobility) in record time.

-

Aerospace and Defense

Aerospace and defense companies need to develop high performing materials and components that hold up in extreme environments. The Citrine Platform helps customers design materials, processes, and manufactured parts that meet these objectives with a combination of materials-specific AI and smart data infrastructure.

The Citrine Platform brings agility to your R&D teams, helping them efficiently explore new materials and processes. This can also help with other key business goals, such as supply chain resilience, improved sustainability, and adaptation to regulatory shifts.

“The Citrine platform’s ability to model two key properties that were key bottlenecks for us has helped us significantly accelerate our R&D.”

– VP, Product StrategyAerospace and defense companies can use the Citrine platform to:

- Co-optimize products and materials

- Accelerate the qualification of additive materials processes

- Transition to new energy sources

- Speed the development of high-performance materials for extreme environments

- Predict lifetime properties (e.g., fatigue and creep)

Download the eBook

Read how the Citrine Platform can be used to accelerate the qualification of new additive manufacturing materials and processes. Materials informatics can help you meet your strategic sustainability goals.

-

Automotive

The Citrine platform helps automotive OEMs and suppliers develop new materials for electric vehicles, lightweight existing products, and design for performance while considering complex regulatory and supply chain trade-offs.

By facilitating rapid development of new materials and the co-optimization of materials and finished parts, the Citrine platform enables automotive OEMs and suppliers to accelerate innovation and maintain the differentiation of their technology while balancing changing consumer preferences and regulatory requirements.

“Citrine’s approach is essential to our company’s success.”

– Chairman of a high-performance automotive battery companyAutomotive companies can use the Citrine platform to:

- Co-optimize vehicles and lightweight materials

- Accelerate the qualification of additive manufacturing processes

- Rapidly design components and systems for use in electric vehicles

Download the eBook

Learn how the Citrine Platform can be used to optimize battery configurations and reduce time spent testing.

FAQs

-

How can AI help me optimize chemical formulations?

Optimizing and reformulating chemicals and materials is a complex challenge with many possible ingredients and processing parameters and many different properties to optimize simultaneously. AI can easily cope with this complexity and systematically review all the options, predicting the properties of hypothetical formulations. Perhaps more importantly,it can also estimate the uncertainty in its own predictions, so that you can make strategic decisions about which experiments to do next in the lab. Citrine Informatics has consistently seen a reduction by about 50-80% in the number of experiments needed to hit target properties over a customer’s existing design workflows.

-

How can AI help me optimize chemical production processes?

The production of materials and chemicals involves many different raw materials and many different processing steps, each with their own specific parameters. AI can simultaneously optimize the formulation and the processing to optimize energy use, cycle time etc. Citrine’s AI platform also enables you to set up allowable processing parameters as part of the AI search space, making sure the products suggested by R&D are feasible on scale up to production.

-

How can AI help me prove the effectiveness of my chemical product?

Raw material suppliers are often asked for advice by their customers about which product will work best for them. They can use AI to predict the properties of a formulation using their product and compare this to predictions for formulations using alternative raw materials. In this way they can show their customers not only how much of an impact their ingredient has on final properties but also how certain they are of their information. This webinar shows you how this works.

-

How can AI help me improve the sustainability of plastics?

AI is being used in several different ways to improve the sustainability of plastics. The first way is to optimize the technical performance properties of the plastic, such as increasing mechanical strength while decreasing density, particularly important in automotive applications. The second way is by reformulating existing polymer grades to maintain performance, while removing problem ingredients such as PFAS. The third way is by moving away from fossil-fuel feedstocks to bio-based feedstocks. An example of this that used the Citrine Platform was used to develop bio-based plastics. Lastly, AI can be used to adapt compound formulations rapidly as batches of post-consumer recyclate vary during mechanical recycling, and to optimize yields in chemical recycling. This webinar shows you how this works.

-

How can AI help me improve the sustainability of coatings?

AI is being used to optimize the processes used to make the fillers used in paints and coatings (to reduce energy use); to reformulate coatings without PFAS and VOCs; and to develop bio-based polymers used in paint formulations. Learn more by watching this webinar.

-

How can AI help me formulate clean beauty products?

AI is being used to determine possible plant-based alternatives to petroleum-based ingredients and to reformulate without problem preservatives and surfactants. By accelerating product development clean products get to market quicker. See how this works by watching this webinar.

-

How can AI help me replace problem ingredients?

The Citrine Platform analyzes the chemical formula and molecular structure of ingredients to understand which features of the chemicals are critical to the overall formulation performance. It creates a unique ‘fingerprint’ for each molecular component, capturing its structure–property relationships. This enables the platform to identify alternative ingredients that can replace problematic ones, while simultaneously optimizing for multiple performance objectives. Examples of this include the removal of PFAS from adhesive formulations. Learn more about this from this webinar.

-

How can AI help me reduce ingredient costs?

With AI you can consider many different objectives at the same time, with fewer experiments. By automatically calculating ingredient costs of candidate formulations, you can rank based on cost and visually see the trade-offs in performance and cost. Here is a case study showing that. Alternatively, companies that produce the same product in different countries, can use AI to formulate products in each country using local ingredients, while maintaining quality and consistency. A second case study showing how this works.

-

How can AI help me adapt to regulations?

Using AI in R&D enables you to get ahead of regulations or respond in an agile way when they are imposed quickly. By accelerating product development and enabling ingredient substitution, the Citrine Platform helps our customers keep pace with regulations on PFAS and cosmetic ingredients and recycled content quotas. Example Case Study.

-

How can AI help me adapt to supply chain issues?

Price volatility and unavailability of raw materials can disrupt production and lower margins. AI can be used to a, understand which ingredients are irreplaceable, b, determine a plan B formulation, c, reformulate to reduce costs. A webinar on this topic can be found here.