Materials Informatics is a rapidly developing field. As we learn how to do new things better, we develop terminology. This post is part of our “demystification” series.

What is a Design Space?

AI models predict properties (e.g., Young’s modulus) based on input parameters (e.g., composition and heat treatment temperature). The set of possible input parameters that are to be run through the AI model is the design space.

Materials and Chemicals development has high-dimensional design spaces

A researcher might want to vary both composition, which in a formulation might have dozens of ingredients, and process parameters from multiple processing steps at the same time. Traditionally, it would be very expensive to explore the whole of this high-dimensional design space, even using advanced Design of Experiment methods. Researchers would often instead use their scientific intuition to narrow down and investigate a particular area.

What determines the boundaries of the design space?

Both practical and theoretical considerations are important in setting up the design space.

Theoretical Considerations

From a theoretical perspective, the researcher will know that some inputs to the model are important, or feasible, and others are not. To give a simplistic example, the kiln temperature is an important input (dimension in the design space) for a ceramic that is sintered, but the day of the week that the batch was run should not be. In a formulation project, there may be thousands of possible ingredients, but researchers might know that there needs to be particular types of ingredients in a particular ratio. This domain knowledge can be translated into a set of rules that define the design space.

Practical Considerations

From a practical perspective, data accessibility is important. If an input parameter cannot be measured, or there is no historical data, then it cannot be used. Another practical consideration is what is physically possible. In the previous example, a researcher may be interested in kiln temperatures up to 1500 deg. C, but the production line kilns only go to 1200, or the product manager knows that the extra costs involved in higher temperatures would not be acceptable to end customers.

Lastly, every new dimension, and every incremental change on that dimension, creates exponentially more calculations for the AI model to run through. A typical run of an AI model at Citrine takes minutes not hours or days. But there is still a cost, and so this is a consideration. These practical aspects set constraints to the design space.

What is an Enumerated Vs a Continuous Design Space?

Enumerated

An enumerated design space is one where the input parameters are explicitly set out and the AI model steps through them systematically. If mixing time were an input parameter, it could be defined in the design space as ranging from 5 minutes to 60 minutes in steps of 5 seconds. While it may be possible to mix the ingredients for 5.63 seconds, this value will not be evaluated by the AI model.

| Ceramic Candidate | Powder weight (kg) | Mixing Speed (rpm) | Mixing time (s) |

|---|---|---|---|

| 1 | 250 | 10 | 5 |

| 2 | 260 | 12 | 10 |

| … | … | … | … |

| 10 | 350 | 30 | 60 |

Continuous

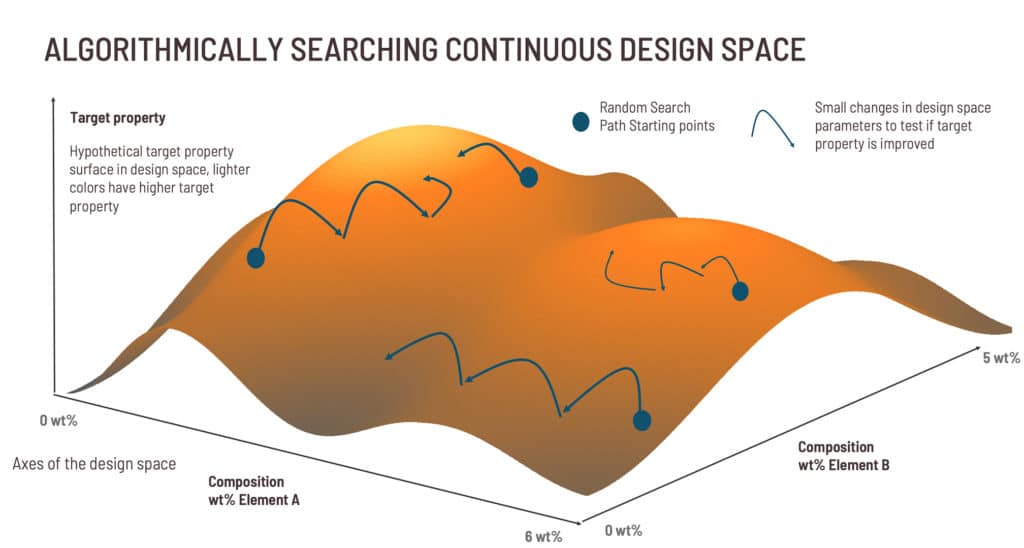

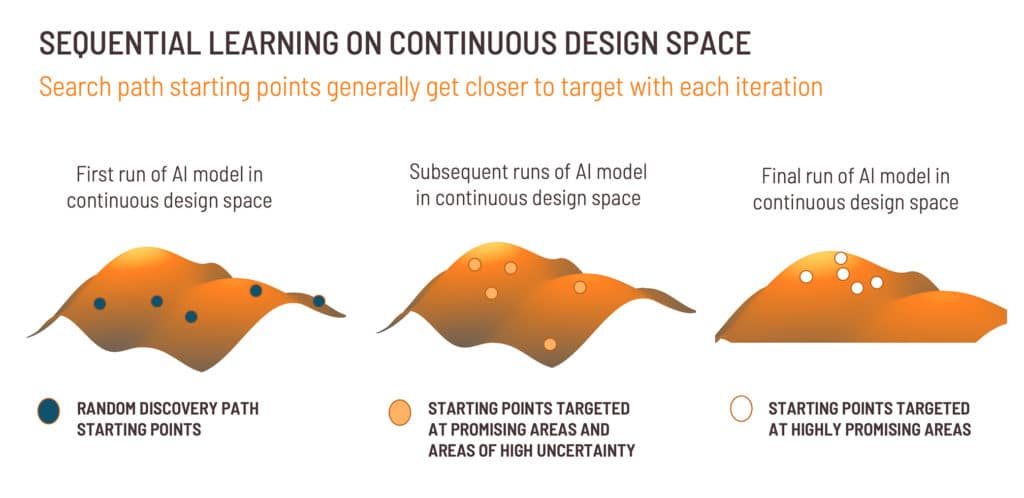

In a continuous design space, constraints on the input parameter are still set, (e.g., mixing time 5 minutes to 60 minutes), but the incremental steps in between are not set. Instead, smart algorithms are used to explore the whole design space and narrow down promising search areas.

How can design spaces be used during materials and chemicals development?

Capturing corporate knowledge

As described above, the boundaries and dimensions of a design space can depend on both the knowledge of customer and business requirements, and on an understanding of the underlying science. This knowledge is captured in the design space which is a reusable digital asset in the Citrine Platform. If a researcher leaves the company, that knowledge is still useable, preventing unfeasible candidates from being synthesized and tested. However, it is not static; a design space can be tweaked as customer requirements or the regulatory environment changes.

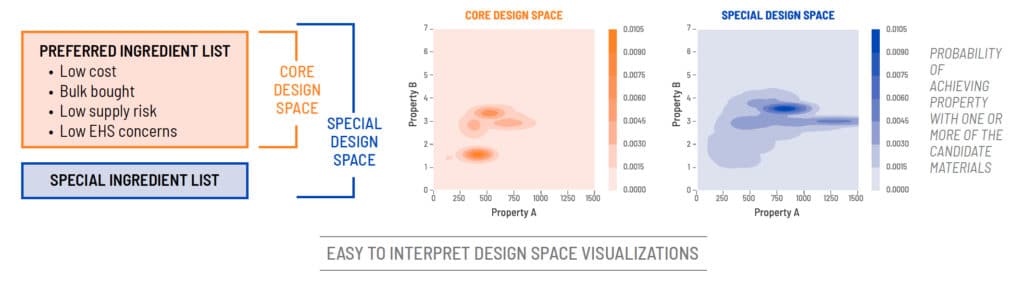

Preventing inventory sprawl

Using new ingredients can introduce costs, not only in terms of their purchase costs, but also in terms of inventory management. Design Space Visualization can be used to compare the achievability of target properties with and without the new ingredient. Research workflows can include this step to justify or discount the use of a new ingredient.

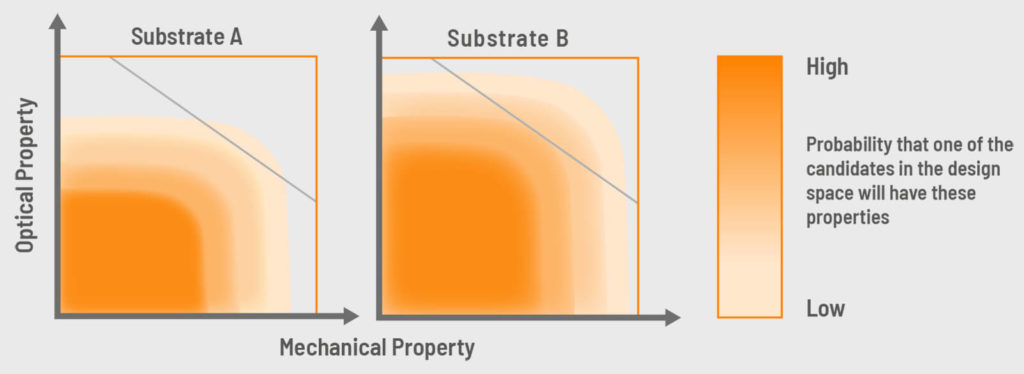

Focusing research

Citrine has developed patented technology to assess the likelihood of achieving target properties in a design space. This gives extra information to researchers and research leaders who are making investments in resource intensive experiments. Researchers can compare the likelihood of success in a particular research direction, before significant investment has been made, which focuses resources on areas most likely to create value.

Example uses:

- Which of 11 glass substrates is most likely to achieve the optical properties needed?

- Are rare earth elements required to make high-performance batteries?

- Will using biodegradable ingredients in the solvent reduce the likelihood of hitting target properties?

Find Out More

In this case study 11 different substrates were treated as different design spaces so that research leaders could make decisions on which substrate to concentrate their efforts on.