The Customer

A global top 5 adhesives and sealants company needed to retain their innovation advantage across their expansive product catalog. Staying ahead of regulations and meeting shifting market demand was posing a challenge to their competitive edge. After first trying to build AI capability internally, and finding it difficult to scale, they turned to Citrine.

The Problem

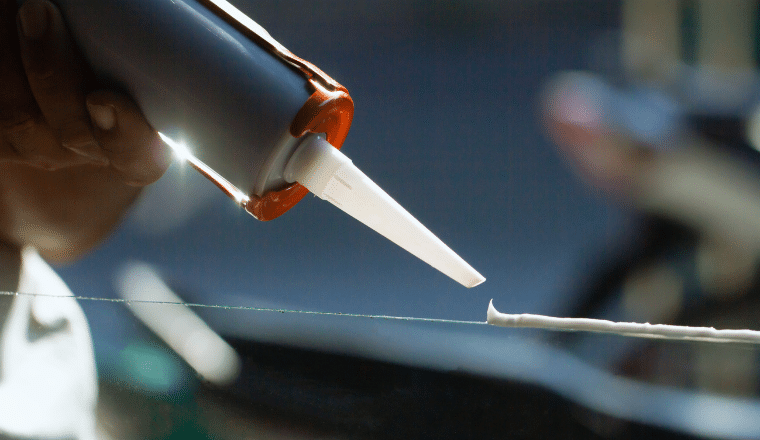

In their first application of the Citrine Platform, the customer sought to reformulate a pressure sensitive adhesive to exclude PFAS while maintaining current performance – a project estimated to span five years. The customer had already made significant investment into the project, and yet prior to using the Citrine Platform, they struggled to achieve the critical breakthrough necessary to meet their targets.

The Process

In the first month, the customer quickly on-boarded and trained to be able to use the Citrine Platform autonomously. Within their first three months, they created an AI model to screen small molecules as a surrogate for DFT/MD calculations. They then created a model to assess millions of ingredient combinations, successfully narrowing them down to 30 viable candidates for the PFAS project. Over the next two months, a single user autonomously generated 25 new Al models for use on subsequent projects. The customer quadrupled the number of projects and users on the Platform, significantly accelerating their development.

The Outcome

- Within the first 4 months, the customer identified the breakthrough candidate that would successfully meet performance targets without PFAS, impacting much of their product catalog.

- The customer team estimated that they would now be able to get the new formulation to market in two years rather than the five years the customer had originally planned for – 2.5x faster.

- The customer built data architecture around Citrine’s GEMD (Graphical Expression of Materials Data) schema and planned for subsequent data integration alongside rapid enterprise expansion.