R&D leaders on the path to digital transformation often face the same question: should we implement an ELN, a LIMS, or a Materials Informatics system first? And in which order? The choice is made more confusing by vendors claiming their tools can do everything in one integrated solution. After more than a decade of working with hundreds of companies, here’s our perspective on how to think about these options.

What Are ELN, LIMS, and Materials Informatics?

- ELN (Electronic Lab Notebook): A digital notebook for capturing unstructured research data, protocols, and notes. Its value lies in collaboration and record-keeping.

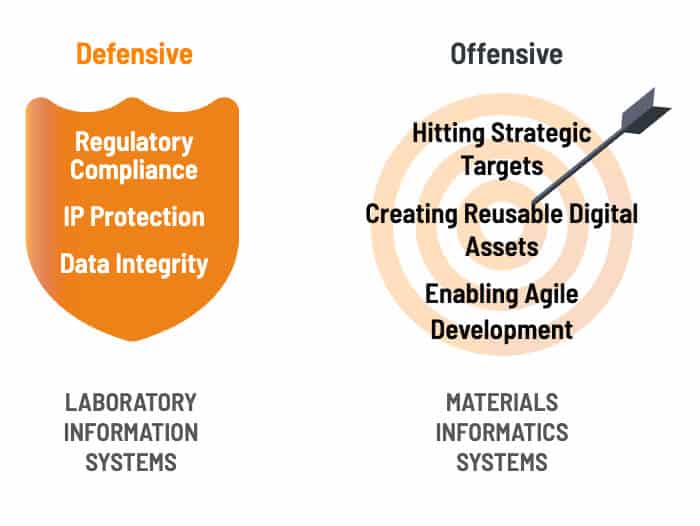

- LIMS (Laboratory Information Management System): A system for managing structured lab operations – tracking samples, workflows, and data integrity. Particularly useful for high-throughput or compliance-heavy environments.

- Materials Informatics (MI): A data-driven approach to product development that uses AI and ML to recommend experiments, formulations, and processing conditions. The goal is faster, cheaper, greener products by reducing trial-and-error and extracting more value from existing data. In short:

ELN/LIMS are about data management; MI is about data utilization. Both matter, but sequencing them well is crucial.

Strategy 1: The “All-in-One” Solution

Some vendors promise a single platform that combines ELN, LIMS, and AI. The appeal is clear: one system to record experiments, manage samples, and generate insights.

In practice, though, “all-in-one” usually means “good at none.” Adding true AI capabilities takes years of focused investment. Many lab software companies only recently bolted on AI features, and the results often disappoint.

Common challenges we’ve heard from R&D leaders who tried this route include:

- Minimal support from people who actually understand materials science.

- Needing thousands of data points before seeing any results.

- No ability to do inverse design (working backwards from desired outcomes).

- Limited chemical awareness or inability to handle formulations with complex constraints.

- Rigid data models, poor user interfaces, and lack of uncertainty quantification.

The lesson: if AI is an afterthought in a lab system, you’ll likely end up using the ELN/LIMS functionality but still need a separate MI solution.

Strategy 2: ELN/LIMS First, Then Materials Informatics

Another common belief is that you must get all your data perfectly organized before you can use AI. On paper, this seems sensible. In practice, it often backfires.

Think of it like building a garage for your cars (data). You spend years and millions building a beautiful garage – only to realize you built it in the desert, far from where you actually drive. Moving it later is almost impossible. Many companies build elaborate ELN/LIMS systems without clarity on how that data will deliver value, leaving scientists wondering: “Why are we doing all this?”

ELN/LIMS can improve workflows and compliance, but the ROI is often fuzzy and long-term. Meanwhile, you delay the tangible benefits that AI can deliver today – like fewer experiments, faster product launches, or cost reductions.

In our experience, companies that try “ELN/LIMS first” risk fatigue and stalled momentum. Data clean-up becomes the goal itself, rather than the means to better products.

Why waste years feeding a data system when your competitors are benefiting from AI?

Strategy 3: Materials Informatics First, Then ELN/LIMS as Needed

We’ve found the most effective strategy is to start with Materials Informatics, then decide what ELN/LIMS infrastructure you truly need.

Why this works:

- Smarter choices later. Once you know what data fuels your MI success, you’ll be better equipped to choose (or skip) an ELN/LIMS. Many clients find they need less infrastructure than expected, or that MI reduces the scope of an eventual ELN/LIMS project.

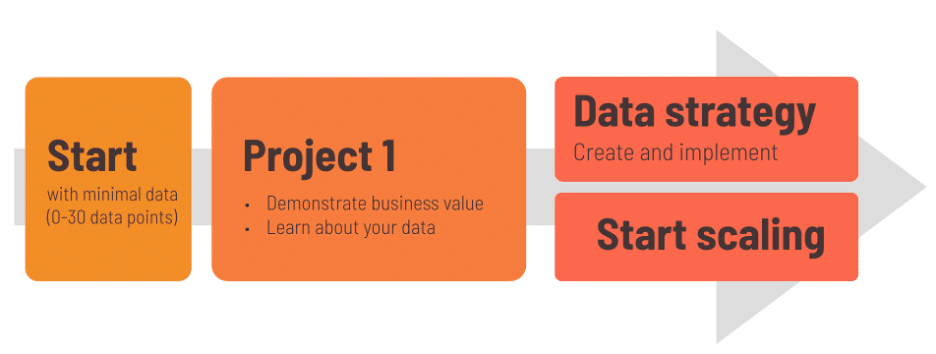

- Faster ROI. MI projects deliver results in months, not years. Within a few cycles, you may see optimized formulations, reduced costs, or sustainability wins.

- Lower upfront effort. You don’t need to “boil the ocean.” Most projects start with a modest dataset – often 50 data points in a spreadsheet – and expand from there.

- Clearer value. AI outcomes are easy to measure: better products, faster timelines, lower costs. This makes it easier to justify further investment in data.

This “AI-first” approach flips the script: optimize now, then organize what proves useful. It creates a positive feedback loop where AI shows what’s possible, and that success motivates better data practices.

Conclusion

Choosing between ELN/LIMS and Materials Informatics doesn’t have to be overwhelming. Both have value – but sequencing matters.

Starting with MI delivers quick, tangible results and helps clarify what (if any) additional infrastructure is needed. Starting with ELN/LIMS risks long delays, high costs, and unclear ROI. And all-in-one promises? Often too good to be true.

Digital transformation is a journey. By leading with tools that directly accelerate innovation, you ensure that data management efforts support real outcomes instead of becoming an end in themselves. With the right partner, you can make better products, faster and more sustainably – and avoid common pitfalls along the way.

Ready to learn more about best data practices?

Join us for an insightful webinar on “Smart Data Practices for AI-driven Research and Development,” where you’ll learn how to optimize your data strategies to harness the power of AI and see state-of-the art data ingest tools.

Smart Data Practices for AI-driven Research and Development

- What good AI-ready data looks like

- Effective data management strategies

- How the latest technology is making it easier to ingest data into AI platforms