Citrine | Platform

The AI-driven product development software for materials and chemicals

The Citrine platform is an integrated suite of software products and services that help companies capture what they know, use artificial intelligence to generate new insights, and share those insights to create value.

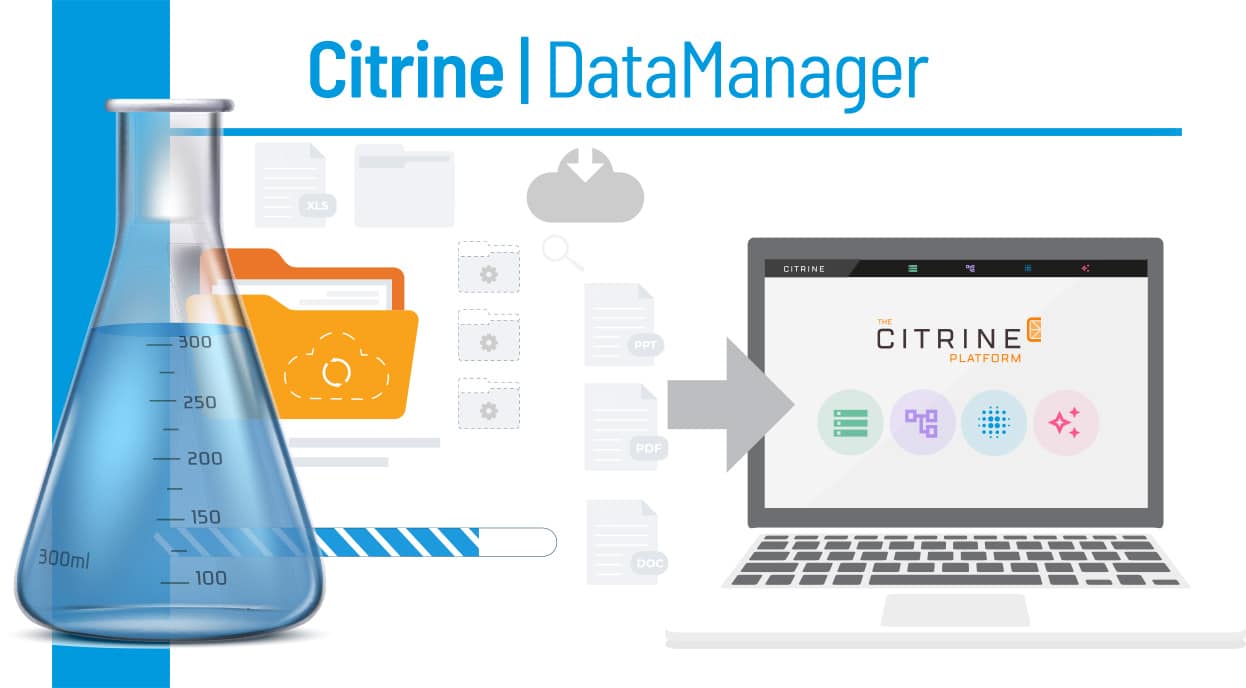

Citrine DataManager: Capture what you know

Spreadsheets. Lab notebooks. Proprietary databases. Even hand-written notes. Your intellectual property is spread across formats, divisions, and even geographies. Citrine DataManager helps you capture all your teams’ knowledge so you can unlock its value.

Learn more

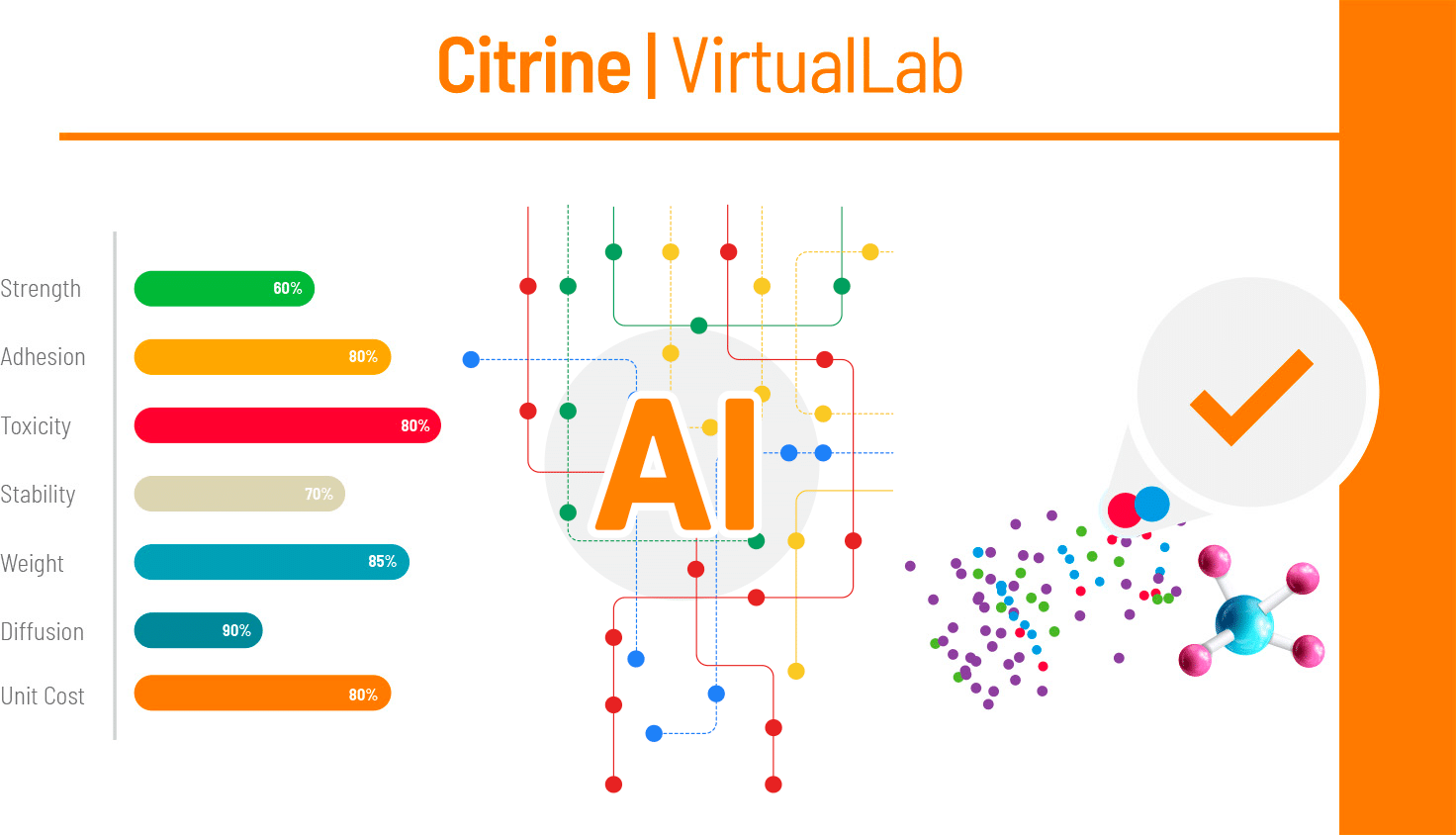

Citrine VirtualLab: Use AI to work smarter

Help your next breakout success break out of the lab. Citrine VirtualLab helps you get the features you need – whether that’s lower cost, better performance, greater supply flexibility, more sustainability, or something else.

Learn more

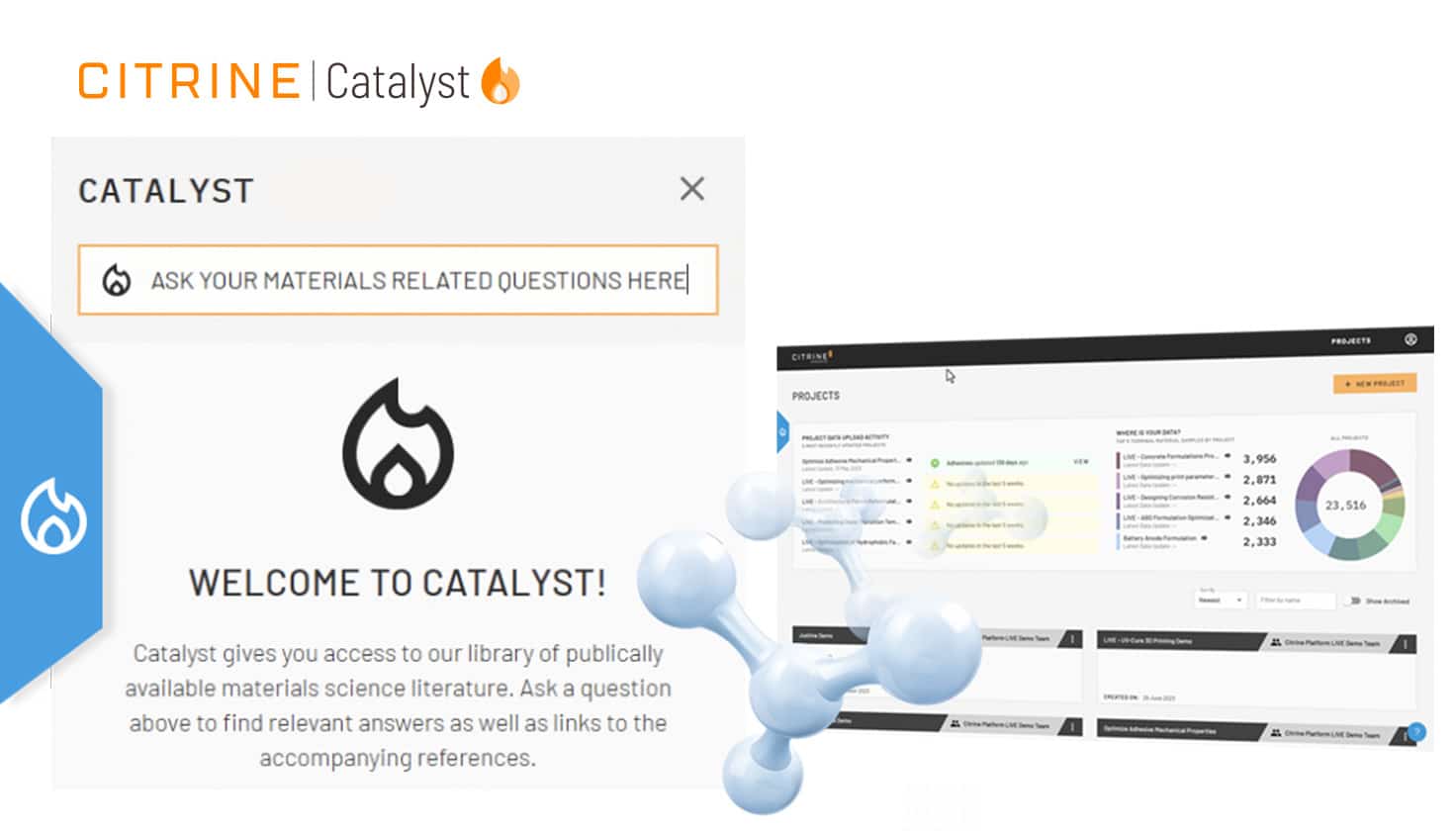

Citrine Catalyst: Meet your digital research assistant

Find the supporting research you need, when and where you need it. Citrine Catalyst lets you ask questions about materials and chemicals using natural language – and get quick, reliable answers from industry journals and prepublication articles without interrupting your workflow.

Learn more

Citrine Professional Services:

Bring it all together

With Citrine Professional Services, you’ll have all the help you need. We share best practices so you can quickly generate ROI and go to market faster than ever.

Enterprise-ready

Easy to start, easy to use

You can get started with Citrine in 1 day. Our SaaS platform is hosted on Amazon AWS, with easy-to-use tools and a dedicated support team to help you quickly ingest data from multiple sources. Find out more ›

Scalable and flexible

The Citrine platform is hosted at Amazon Web Services (AWS), the largest global cloud services provider. Our solution is reliable and rapidly scalable, whether you have small dedicated projects or a global, multi-business unit deployment. Find out more ›

World-class security

Your data is hosted in its own virtual private cloud, with end-to-end encryption. We are ISO 270001 certified, demonstrating our dedication to information security, data protection, and continuous improvement. Find out more ›

Committed to your success

From initial planning through implementation and ongoing support, we’re committed to your success, with dedicated account teams, online documentation, regular training sessions, a video repository, and more. Find out more ›

Citrine | How do we help?

Whether you are an R&D Manager, an Application Engineer, or a Product Expert, in Specialty Chemicals, Personal Care, or Ceramics and Glass… We can help.

Find out more about how we help companies like yours