Highlights

- 5 months from a cold start (zero data) to a model that suggests successful recipes for additives for carbon fiber

- The first AI model was 4X better at identifying promising candidates than traditional R&D approaches

- AI model suggested a recipe with a result similar to that of existing commercial products after only 3 Sequential Learning iterations

The Customer

KCARBON, Korea Carbon Industry Promotion Agency, based in South Korea, develops cutting-edge carbon fiber manufacturing technology.

The Challenge

KCARBON wanted to produce a new additive recipe for carbon fiber, a formulation that coats the fibers

during the manufacturing process. They were also interested in exploring machine learning-guided product development to see how it performed compared to traditional R&D techniques.

The additive technology improves the physical/mechanical properties of the final fiber and composite. The additive formulation must meet five high priority criteria (other properties are also important and monitored):

A. Meet the dispersion standard

B. Meet processing requirement

C. Improve a physical property

D. Not cause defects

E. Improve a mechanical property

Citrine and KCARBON began their collaboration prior to any data collection or historical experiments. The lab equipment to synthesize the formulation was a new capital investment. The search space for the project was very large, as many different ingredients could be used in various amounts.

“AI-based material development is efficient and easy-to-use. It helped us go beyond intuitive recipes.”

— Dr. Moonheui Hahn, Project Manager, KCARBON

The Approach

The typical ingredients for the additive formulation are well understood and outlined in literature. The customer team identified a set of two classes of chemicals to use in the project and, together with Citrine, decided on 20 different mixes to run as an initial grid of experiments.

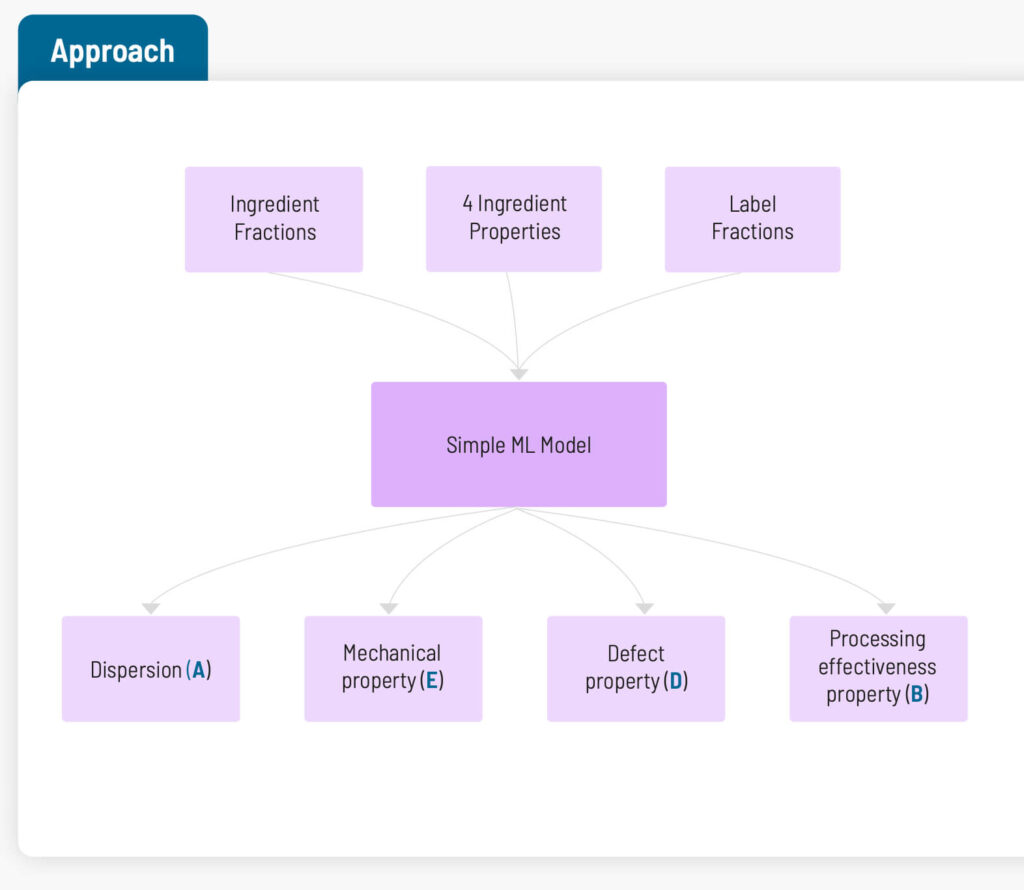

The team ingested the data from the 20 initial experiments into the Citrine Platform, then built and trained a machine learning model on the data.

Using Domain Knowledge

The customer team used their domain knowledge to improve model accuracy through featurization. They labeled each ingredient to sort them into categories using their chemical expertise. The model used both the fractions of each ingredient used and the fractions of each label as inputs, alongside 4 additional ingredient properties. The Citrine Platform has been specially designed to support complex formulation design and facilitate featurization of ingredients via labels.

Setting Constraints and Objectives

The search space that the model explored consisted of the ingredients identified by the KCARBON team. The team then set constraints for formulation candidates:

- Formulation meets the standard for dispersion stability (A)

- Processing effectiveness property (B) within a small range

- Exceeding target value for Mechanical Property (E)

- Below target value for defect property (D)

The candidates that passed all criteria were then ranked by minimizing predicted defect property (D) and maximizing predicted mechanical property (E).

The Outcome

There were 16 formulation candidates suggested by the usual research process and 13 suggested by the initial simple machine learning model on the Citrine Platform. The team at KCARBON mixed and tested all of these formulations. The formulations suggested by the Citrine Platform passed all the constraints at a rate 4 times that of the candidates suggested using the usual intuition-guided research process.

Next Steps

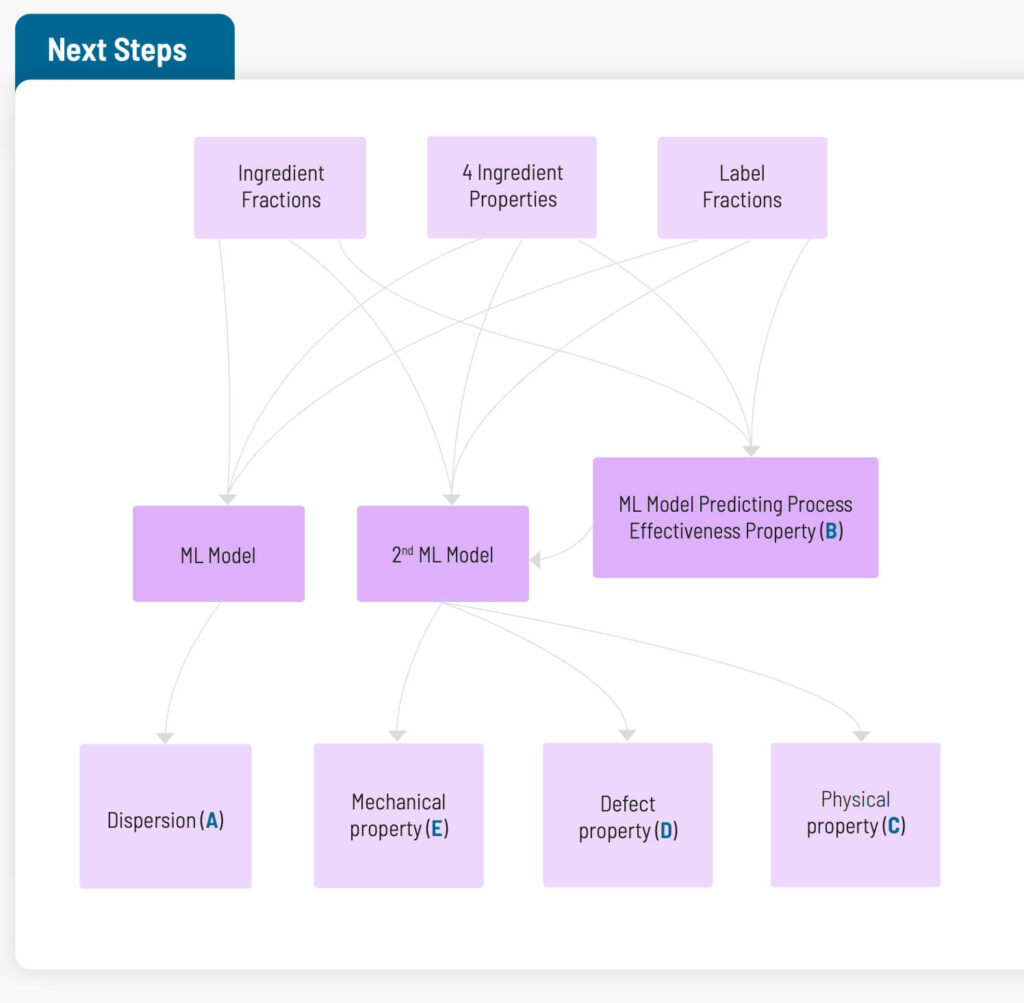

After the success of the first model, the team wanted to co-optimize a property that affects the efficiency of manufacturing composites with other properties. The customer team again incorporated domain knowledge into the modeling approach, using process effectiveness property (B) as a latent variable in the second model. A latent variable is an intermediate property whose data can be modelled from the inputs and whose values may be used as inputs to the main model.

The second model found fewer candidates that met the dispersion and processing effectiveness constraints, and no candidates met the new physical property (C) target. While this was disappointing, it was also useful information. The customer now knows that the current search space does not contain candidates that can co-optimize all 4 properties.

New Product Development Insights

The project produced valuable insights for the customer. They quickly learned that current ingredient inventory was not sufficient to achieve all the performance targets simultaneously, which focused their efforts on which new ingredients to source.

Additionally, the customer team is now fully up to speed with the AIdriven product development methodology, they have a scalable data structure for chemical data, and a clear understanding of candidate selection strategies for data-driven R&D projects.

Summary

With an AI-driven approach to product development, companies can quickly gain valuable insights in a short time frame, even on cold start projects with zero historical data. This approach requires fewer experiments than a traditional design of experiment matrix and produces more valuable results than relying on scientific intuition alone.

Citrine’s global team were able to support the customer team as they started using the Citrine Platform virtually, using synchronous and asynchronous tools. Insights gained during the project are now being used to guide future research directions.

Contact Citrine Informatics to discuss your development projects.