Why high-temperature alloys?

High-temperature alloys are structural materials crucial to several energy production and conversion applications. For instance, nickel-based superalloys typically comprise over 50% of the weight of advanced aircraft engines.

What’s the challenge?

There are a host of complexities related to alloy chemistry, melting and thermo-mechanical processing, heat treatment steps, developed microstructures, and more.

While materials informatics-based methods are well-suited to handle such complexities and leverage large alloy datasets, current approaches are limited by two challenges:

- representation of alloys data while preserving the complete synthesis and processing provenance

- applying machine learning models outside the range of the input data, e.g., predicting extreme-temperature yield strength, is risky and requires accurate uncertainty estimates, reasonable physics-based constraints, or both.

How do we address the challenges?

1. DATA MODEL

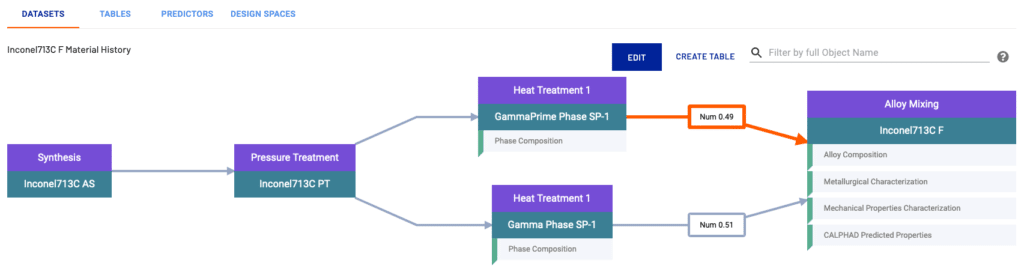

Citrine’s Graphical Expression of Materials Data (GEMD) format enables storing and managing the entire history of a high-temperature alloy, including processing conditions and all characterized properties within a single unified data model.

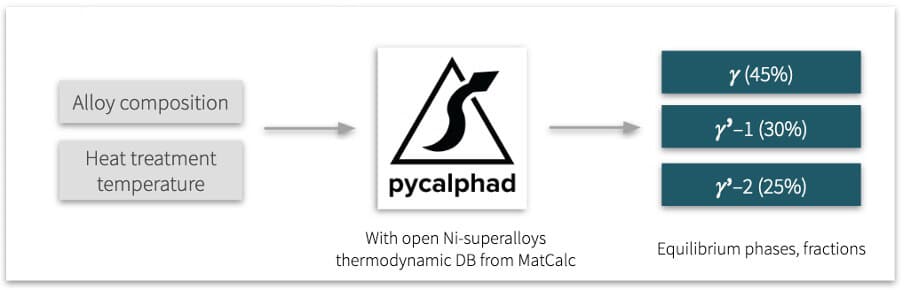

Input from physics-based simulations such as CALPHAD can be readily incorporated within GEMD. For example, shown below is a sample material history of a nickel-based superalloy (Inconel 713C) represented in GEMD, including experimental data (e.g., various heat treatment steps), input from physics-based simulations (e.g., equilibrium phase fractions of precipitates calculated using pycalphad), and measured properties of interest (e.g., high-temperature yield strength).

2. FEATURIZATION

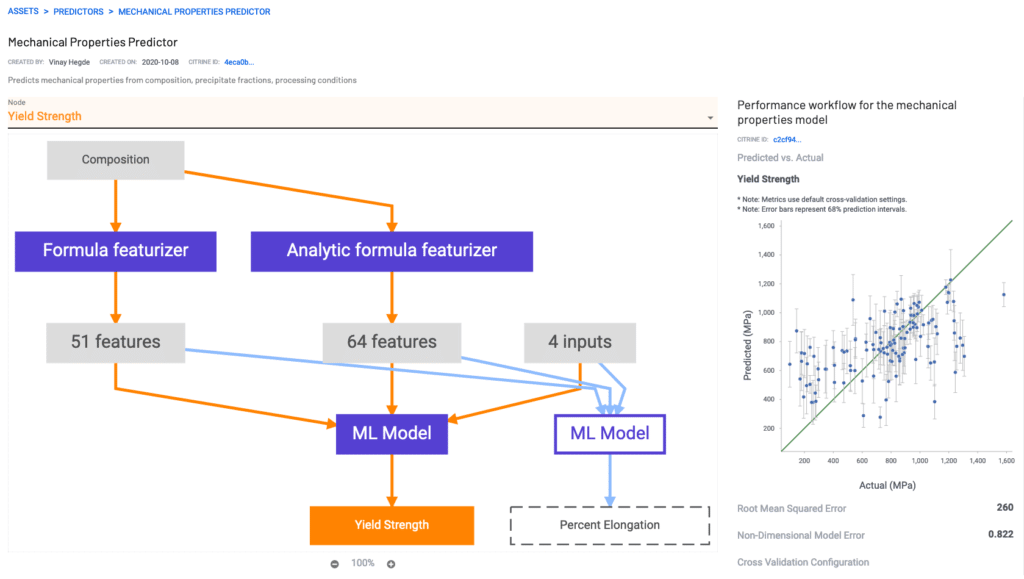

Featurization is the process of converting available materials data into features, machine-readable representations of characteristics and properties of materials. An AI model is then trained to learn the correlations between such input features and target properties, and to predict the properties of material candidates outside the realm where data is currently available. Predictions outside of current training data will of course be uncertain and it is important that robust estimates of uncertainties accompany every prediction.

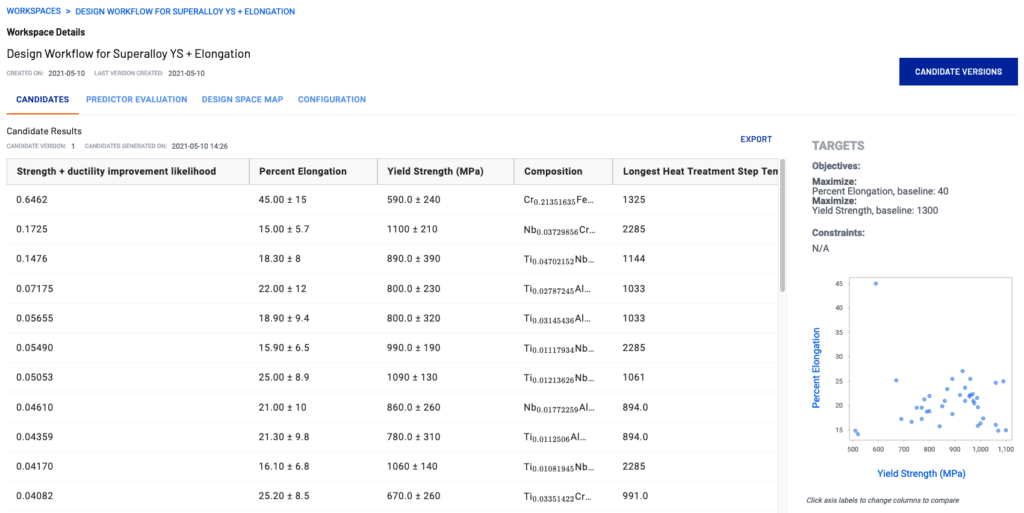

The Citrine Platform enables easy featurization of alloys based on their chemical composition, processing conditions (e.g., total heat treatment time), and predictions and constraints from physics-based models (e.g., overall precipitate fraction from CALPHAD). The models produced can then be employed to search for a new, improved high-temperature alloy candidate in the design space of interest.

Example Models

Below are sample models built on the Citrine Platform to predict the yield strength of superalloys at high temperature.

The Citrine Platform enables comprehensive alloy data management with full provenance, and accelerated alloy design using physics-informed informatics workflows.

Find Out More

You can find out more about Citrine’s External Research Department here.