Executive Summary

Huntsman Building Solutions used the Citrine Platform to:

- Reduced reliance on full-scale fire testing

- Shortened development time

- Delivered a high-performing, sprayable, and regulation-compliant foam

The Customer

As a leading manufacturer of spray foam insulation, Huntsman Building solutions are using 110 years of experience to pioneer energy efficient, reliable, sustainable polyurethane spray foam insulation for a range of applications.

“In the old workflow, it took a chemist 6 months to come up with a starter formulation. With the platform, they can get a starter formulation on day 1.”

Objectives

Meeting regulations relating to flammability is key for Huntsman, but large scale fire tests (such as ASTM E84) are complex, expensive and time consuming as they are carried out off site by an independent tester. They are an important part of regulatory testing for product certification and a big milestone in R&D. The are carried out after fine-tuning of the formulation once the team are confident based on small scale fire tests run internally and the testing of other important properties.

Huntsman wanted to:

- Establish a development framework that marries deep chemical understanding with rapid data-driven iteration.

- Transform a starting formulation into a formulation capable of passing ASTM E-84.

- Reduce the number of large scale fire tests needed to create a compliant product.

- Deepen materials understanding of the complex chemistry involved.

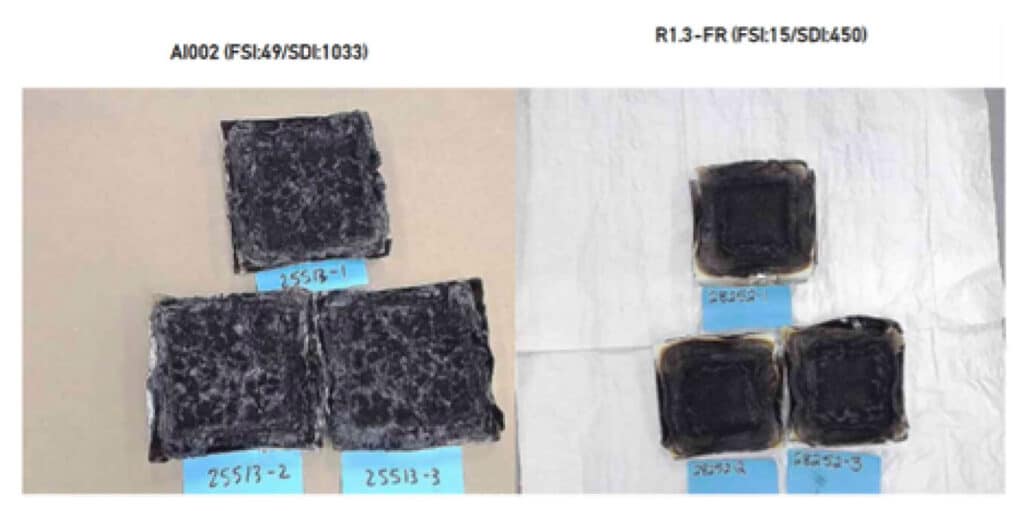

Goal: Transform starting formulation AI002 so that it is compliant

The Process

Data

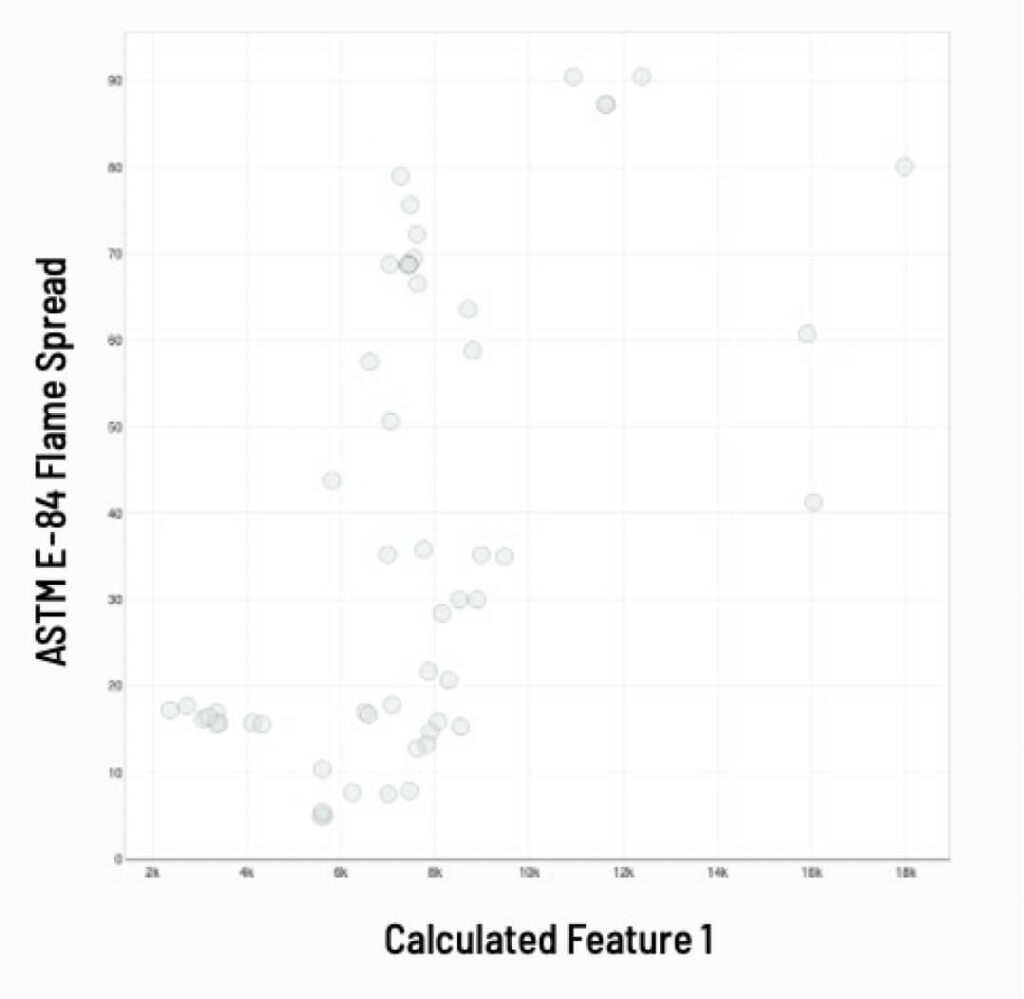

The number of large scale fire tests carried out on AI002 and similar formulations previously was too small to create a meaningful model. So this data was boosted by also using data from small scale fire tests. These tests produce data over time shown as a curve on a chart. The team used their expertise to pick important features of these charts to convert to data to train the models. It is also well-known that Isocyanate index (the ratio of isocyanate (NCO) groups to the total active hydrogen) is important for polyurethane foam production. The Citrine Platform automatically calculates the ratio of ingredients and can use SMILES or InChi notation to generate molecular information about an ingredient which can also be used as a model input.

Search Space

The starting formulation AI002 consisted of polyols, flame retardants, a surfactant, blowing agents, catalysts and Isocyanate. The Huntsman team used their expertise to build a search space where many different options for each of these types of chemicals could be used, but that there was a reasonable expectation of good fire performance given their previous experience. The number of different distinct formulations possible from combining these ingredients meant that it was impossible to test them all.

Modeling

As well as predicting ASTM E-84 smoke development and flame spread, the R-Value (a measure of thermal insulation) was modeled. Other formulation features known to drive high fire performance were also calculated and included as an input to models.

Iterative Experimentation

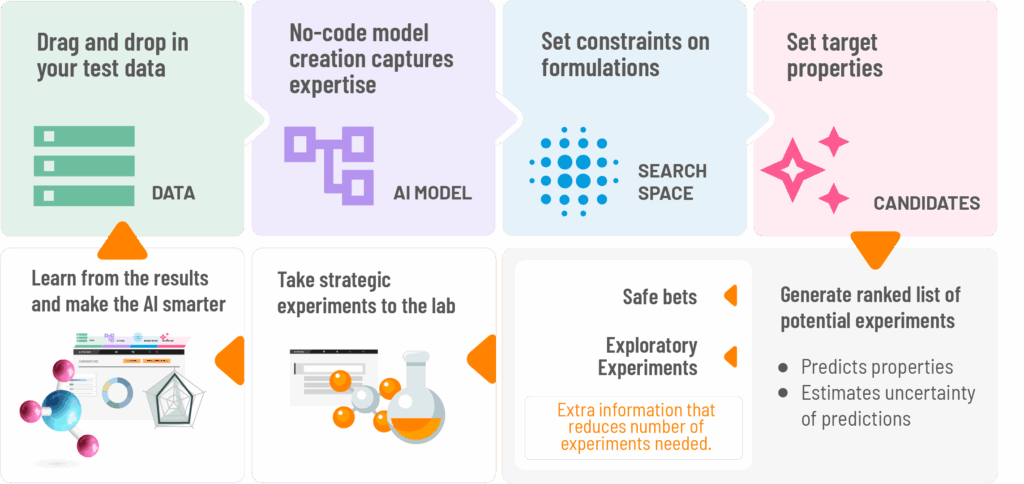

One of Huntsman’s goals with this project was to develop and validate a new development framework – to move to an iterative AI-driven experimentation workflow. It is rare that a company has enough data on exactly the formulation type they are working on to make a perfect model in one go. However, it has been shown, time and again, that using an AI-driven iterative experimentation approach gets to target values quicker than trial and error.

Sequential Learning is the process by which a batch of experiments is suggested based on their likelihood of success, the experts decide which to take to the lab and then upload the results from the experiments back into the Citrine Platform to make the AI model more accurate and better able to suggest the next batch of experiments.

Once first predictive models were built and showing promise a sequential learning process was used to get closer to target values of smoke development and flame spread. Huntsman used two ways improve the AI models in between batches of experiments. Not only did they upload test result data, but they also improved their featurization of the small scale fire tests.

The Results

Better understanding of domain

Nuanced behavior during the small scale tests was “featurized”. Each feature could then be analyzed to understand its impact on flame spread, smoke development and insulation properties.

Compliant formulation

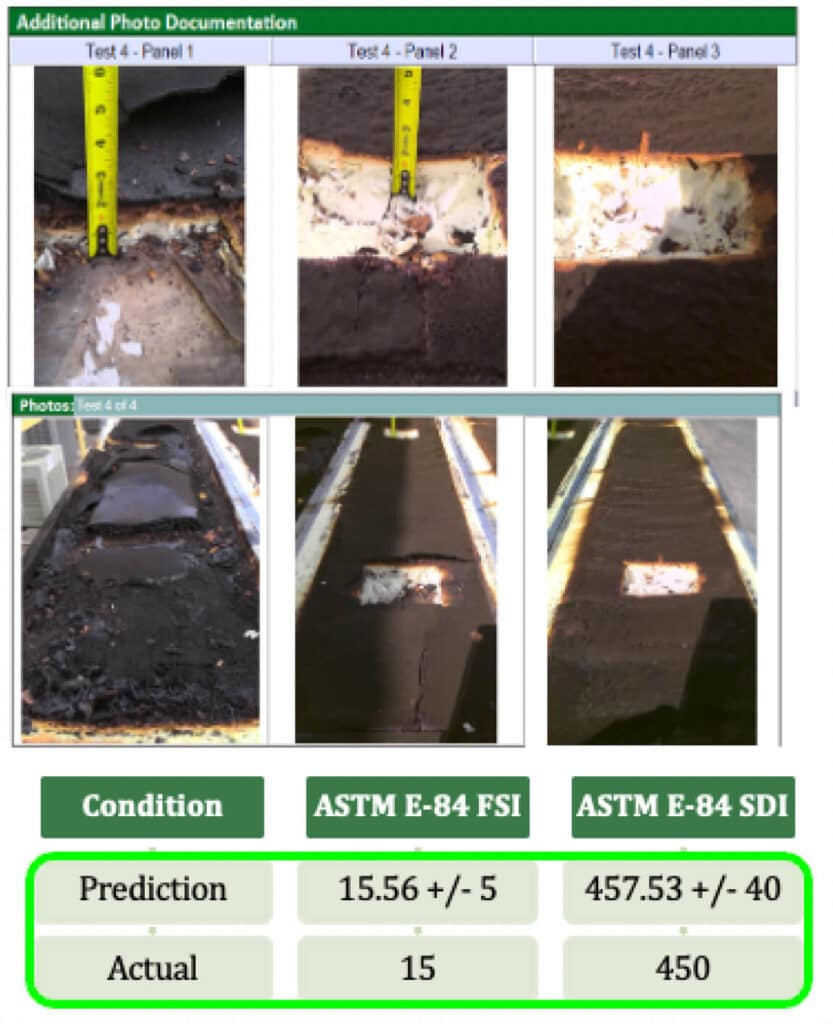

R1.3-FR (an adapted AI002 formulation predicted to perform well) demonstrated significantly improved fire resistance in independent large-scale tests and also retained sprayability and hit physical performance targets.

Increased Productivity

The iterative process, enabled by data-informed prioritization and experimental validation, reduced wasted effort and unlocked new material understanding. The team are now able to prioritize, predict, and produce successful formulations with speed and accuracy.

Highly accurate predictions of large scale test results based on small scale test results

Summary and Next Steps

This success was not an isolated result but a step change in Huntsman’s development process. The team have built confidence in AI-generated insights, reduced reliance on full-scale testing, shortened development time, and delivered a high-performing, sprayable, and regulation-compliant foam.

The success of this project offers a pathway to accelerate future innovation not only in sprayable polyurethane foam but across other rigid foam systems requiring high fire performance, while maintaining efficiency, compliance, and commercial viability.

“This makes AI/ML partners in innovation, not just a recommender.”

— Rogerio Drummond De Souza, Technical Director of Specialties and Roofing Products

While all the information in this publication is to the best of our knowledge and belief accurate at the date of publication, NOTHING HEREIN IS TO BE CONSTRUCTED AS A WARRANTY, EXPRESS OR OTHERWISE. Huntsman warrants only that its products meet the agreed specifications. Typical properties, where stated, are to be considered as representative of current production and should not be treated as specifications. In all cases, it is the responsibility of the user to determine the applicability of such information and the suitability of any product for its own particular purpose. The sale of products referred to in this publication is subject to the general terms and conditions of sale of Huntsman International LLC or of its affiliated companies.