Executive Summary

IMPROVED PERFORMANCE

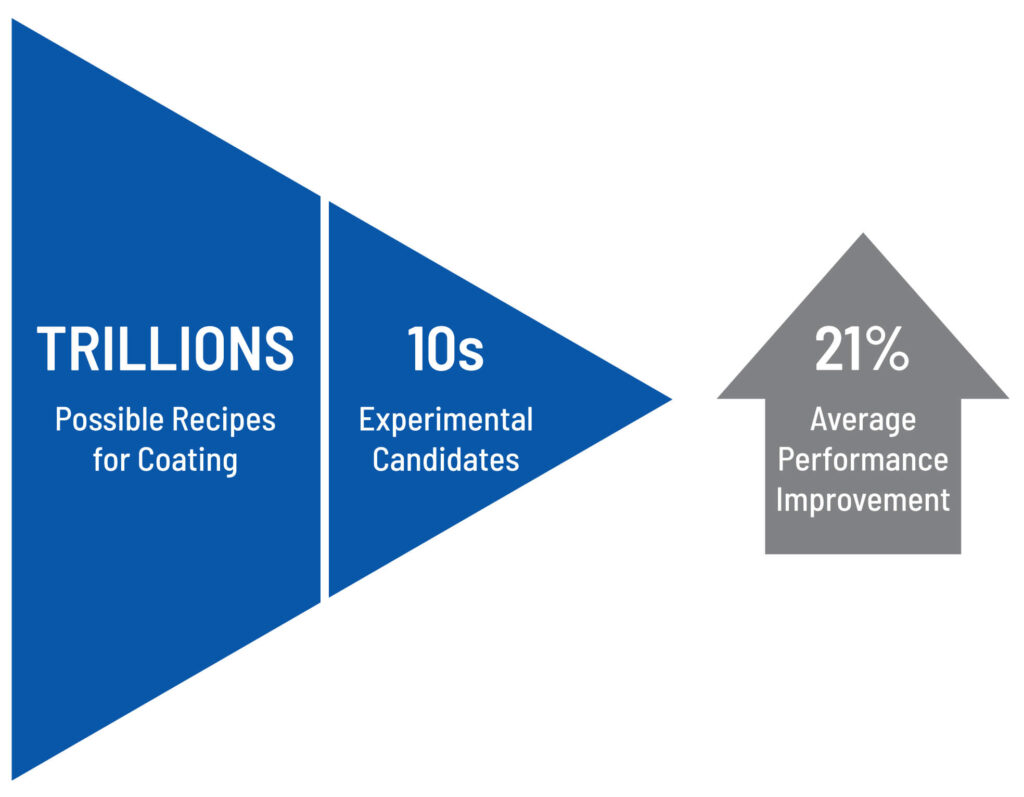

Mechanical performance improved by an average of 21%

NOVEL CANDIDATES

Combination of customer team’s domain knowledge and Citrine’s AI Platform find novel high-performing candidates

FOCUSED R&D WORK

Machine Learning approach assesses trillions of potential formulations to focus on dozens

REDUCED UNCERTAINTY

Novel data processing framework reduced performance uncertainty by 58%

The Challenge

High-performance polymers are increasingly replacing metal in automotive applications as carbon pricing and regulation lead to a focus on lightweighting. Improvements in formulation development mean that strength and stiffness are retained at higher temperatures. As automotive companies partner with formulators during the design process, there is a need for formulators to be able to rapidly assess whether they can develop and produce new polymers that meet the requirements.

A global leader in specialty chemicals and plastics is employing a digital transformation strategy to enable them to win big contracts by dynamically responding to customer requirements. Their challenge was to increase the mechanical properties of a glass fiber reinforced polymer, while maintaining the rest of its property profile.

The Approach

The customer added test data and recipe information from its portfolio – which contains hundreds of products – to the Citrine Platform. The polymer’s properties depend on the bonding between the reinforcing fibers and the polymer matrix. A mix of chemicals, added during compounding, form a coating on the fiber and promote adhesion between the fibers and bulk polymer matrix. The customer’s team has decades of combined experience in the area of formulations development, which they codified and leveraged in AI models on the Citrine platform.

Given the vast number of ingredients that make up a coating recipe, there were trillions of potential candidates – far too many to explore experimentally. Citrine’s Platform was used to optimize recipes and find out which ones were most likely to improve mechanical performance. The team used this information to decide which recipes to make and test next. The results of testing were fed back into the platform and used to retrain the AI models, a process called Sequential Learning.

Sample production in R&D has its own process variability, and the team had to take this into account when assessing each new coating. The Customer team used Citrine’s platform capabilities to not only improve mechanical performance, but also to reduce the performance uncertainty for every new formulation. Using a data-driven normalization process, incorporating reference sample comparisons, glass content variability, and outlier detection, the customer was able to reduce performance uncertainty and increase confidence in the measurements of the test data.

The Results

In just 10 months:

- Sequential Learning has enabled improved performance across all targeted properties

- Novel candidates discovered – not the usual suspects

- Process variability uncertainty reduced by 58%